UV inkjet printers have revolutionized the printing industry by providing fast, high-quality, and durable printing solutions. One of the innovative applications of UV inkjet printers is bottle cap printing. The use of UV inkjet printers on bottle caps has transformed the packaging industry, enabling complex designs, vibrant colors, and more customization.

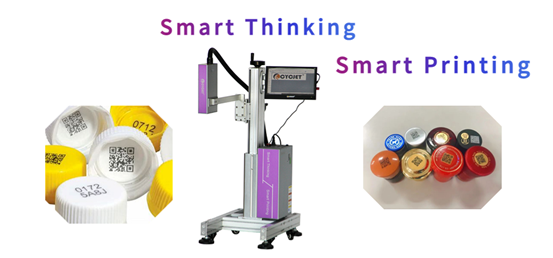

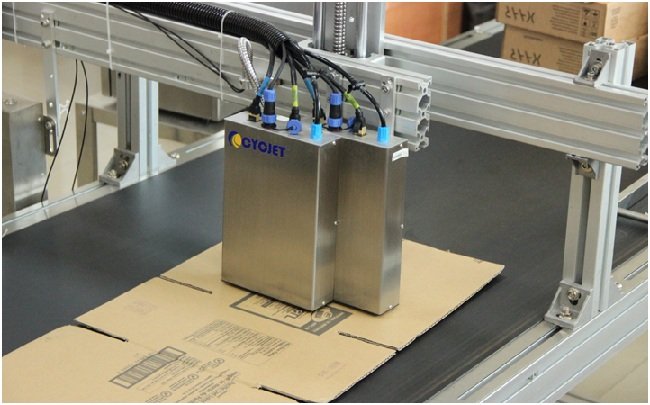

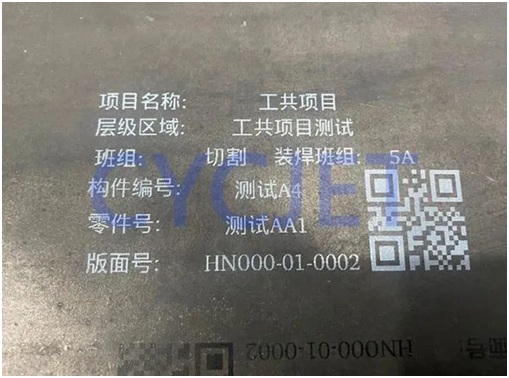

However, using UV inkjet printers on bottle caps provides manufacturers with many advantages. First, the UV inkjet printer can print high-resolution graphics and text directly onto the surface of the bottle cap. This allows manufacturers to create eye-catching designs and logos that enhance the overall appearance of their products. In addition, UV inkjet printers can adapt to a variety of substrates, including plastic, metal, and glass, making them suitable for use with various types of bottle caps.

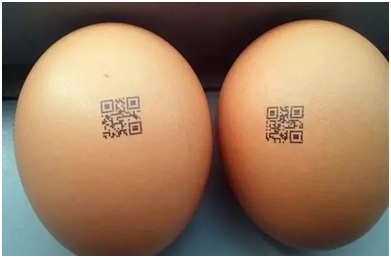

In addition, High-speed Inkjet Printers use ultraviolet (UV) ink, which can be instantly cured by ultraviolet light. The process produces durable, scratch-resistant prints that can withstand the rigors of packaging and shipping. As a result, manufacturers can be confident that their brand and product information will remain intact throughout the supply chain.

The application of UV inkjet printers on bottle caps not only brings benefits to manufacturers but also to consumers. By printing intricate designs and customization options, Online Inkjet Printers allow consumers to easily differentiate between different products on the shelf. This is particularly beneficial for the beverage industry, where products often compete for consumers’ attention.

In addition, the use of UV inkjet printers on bottle caps enables manufacturers to incorporate security features such as QR codes and serialized data to enhance product traceability and prevent counterfeiting. Not only does this protect consumers from buying counterfeit products, it also helps maintain brand integrity.

The versatility of large-format inkjet printers also enables manufacturers to respond quickly to changing market demands. Whether it’s a new promotion, product rebranding, or seasonal changes, UV inkjet printers allow connoisseurs to modify their bottle cap designs within short lead times and without incurring significant additional costs. This flexibility is critical to helping products stay relevant in a competitive market.

Overall, the application of UV inkjet printers on bottle caps provides a superior printing solution that benefits both manufacturers and consumers. UV printers are capable of creating high-quality custom designs that are durable and resistant to wear and tear, making them a valuable tool for the packaging industry.

In summary, the application of Large-Character Inkjet Printers on bottle caps has changed the packaging industry by enabling manufacturers to create vibrant and durable prints, thereby increasing product visibility and brand integrity. Consumers also benefit from UV printers’ enhanced customization and security features. As technology continues to advance, the use of UV inkjet printers on bottle caps is likely to become more common, further shaping the future of packaging design and production.

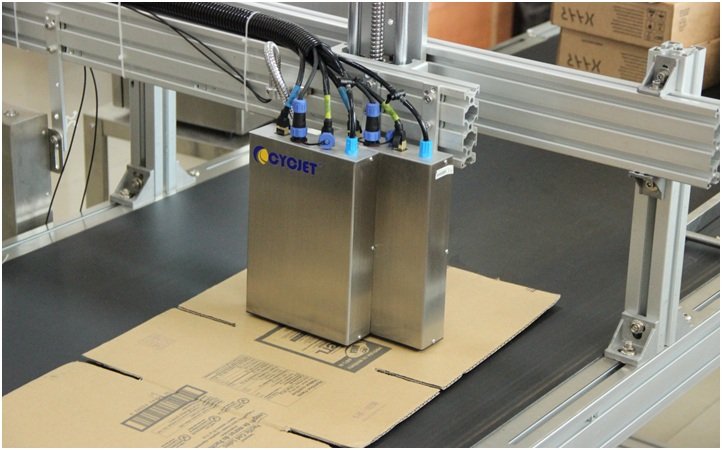

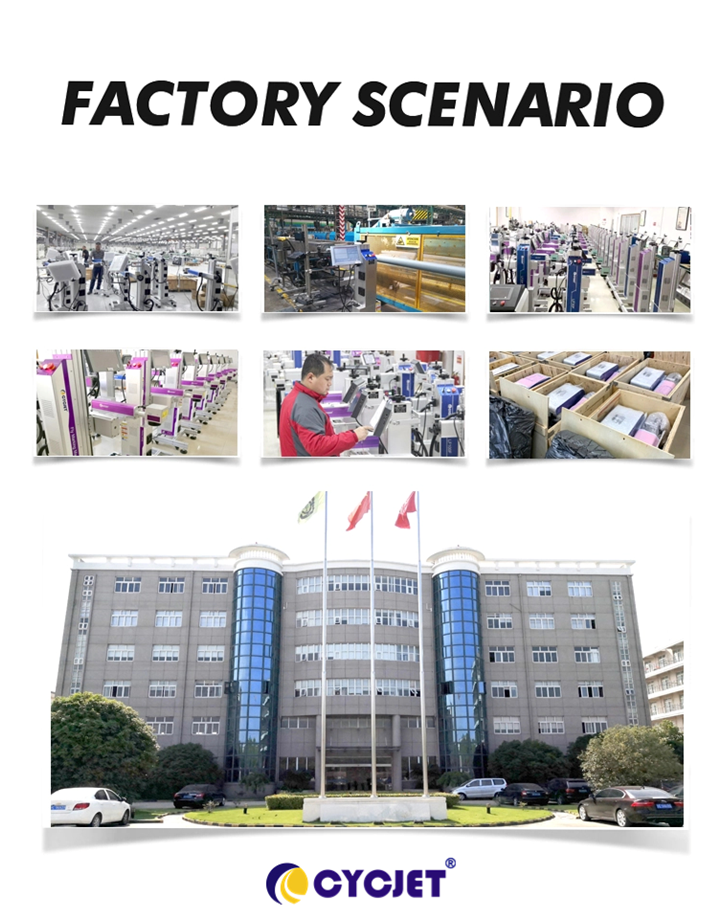

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than 19 years of experience with R& D in different types of handheld inkjet printing solutions, Laser printing solutions, portable marking solutions, and High-Resolution Printing solutions in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/