Continuously advancing technology has led the manufacturing industry to a more prosperous development path, and laser marking machines have gradually become important production equipment in all walks of life. Among them, UV laser marking machines have attracted more and more attention in plastic product marking applications due to their unique advantages.

What is a UV marking machine?

UV Laser Printer is a device that uses a 355nm wavelength ultraviolet laser beam to mark the surface of materials. Its working principle is to irradiate a high-energy ultraviolet laser beam onto the surface of the material, causing the material to undergo a photochemical reaction, thereby forming a permanent mark on the surface of the material that will not fade. Due to its advantages of high precision, fast speed, and high efficiency, it is widely used in various fields.

Application advantages of UV laser marking machine on plastic products

1. Fast marking speed and flexible marking method

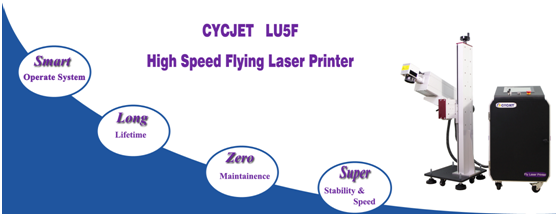

The high-speed laser marking machine uses high-energy UV laser beams to process the surface of plastic products. The marking speed can be as high as 7000mm/s, and a large amount of marking work can be completed in a short time.

2. Good marking effect

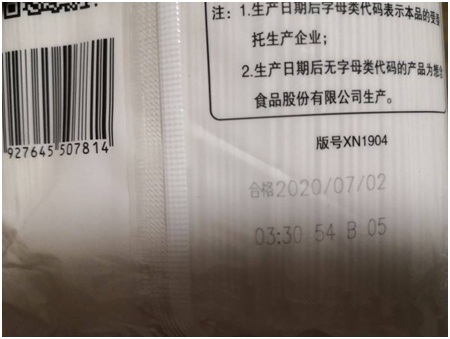

The marks formed by the UV marking machine on the plastic surface are clear, beautiful, and not easy to wear. Silk screen printing is not wear-resistant, and the logo will be worn away quickly, it is easy to print blurred, ghosted, missing characters, and other undesirable effects. However, laser marking can be maintained for a long time and has a high yield rate. At the same time, due to its non-contact marking method, it will not cause any damage to the product surface.

3. Wide range of application

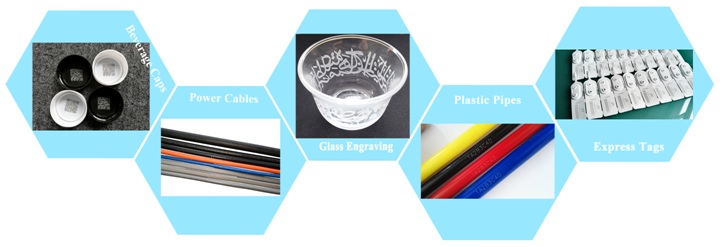

Flying laser marking machines can not only be used for marking plastic products but can also be used for surface treatment of various other materials. For example, metal materials, ABS, PVC, PC, PP, glass, wood, EVA, Mylar tape, PL film, chips, etc., one machine is universal and cost-effective!

In summary, UV marking machines have great advantages in the marking application of plastic products. The precision is as fine as 0.02mm, and there are no ink consumables, which can greatly improve production efficiency. It can also meet the needs of different customers, such as combining with conveyor belts for fully automated visual positioning and marking, saving labor. Therefore, with the continuous advancement of science and technology and the continuous expansion of application fields, UV laser marking machines will be used in more fields.

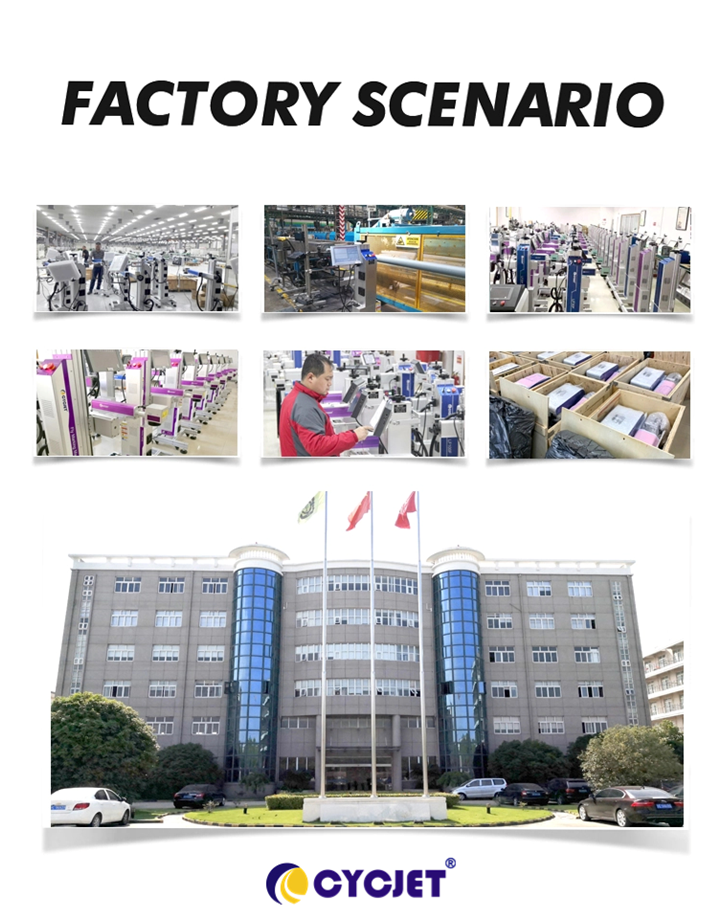

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than 19 years of experience in R&D in different types of handheld inkjet printing solutions, Laser printing solutions, and portable marking solutions, High-Resolution Printing solutions in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB: +86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/