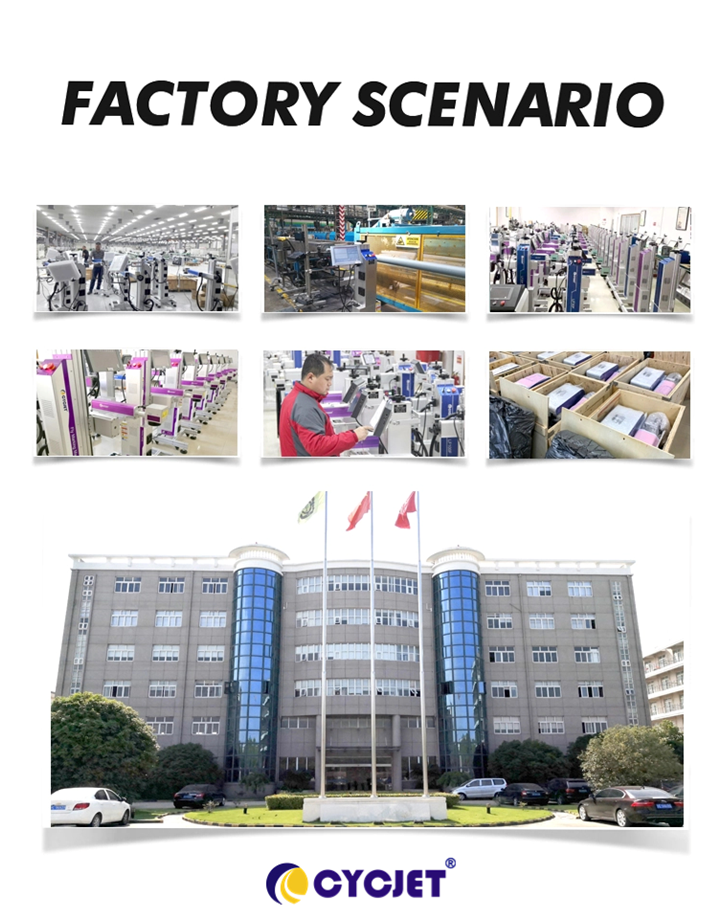

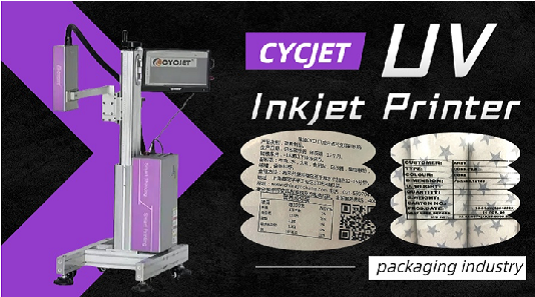

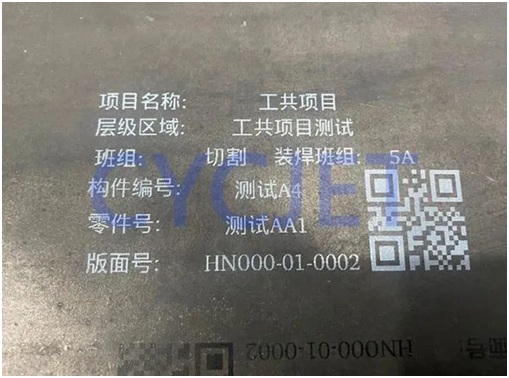

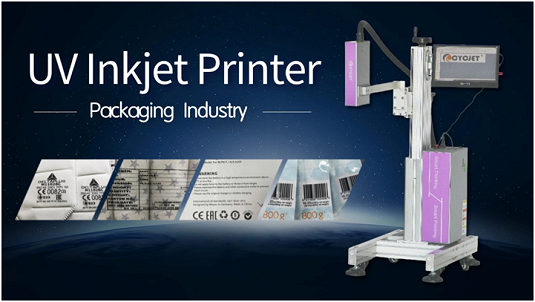

UV inkjet printer is highly efficient and high-precision inkjet equipment that can print text, patterns, barcodes, QR codes, and other information directly on the surface of various materials. It uses ultraviolet light curing technology to quickly solidify the ink during the printing process through ultraviolet lamps, making the printing effect more beautiful and durable. UV inkjet refers to the use of UV ink for coding, which has good effects. The printed content has high adhesion.

With the development of industry, UV inkjet printers have become an indispensable part of product packaging. Especially in the current situation of fierce competition and rapid changes in the market environment, the application of UV inkjet printers is of great significance for enterprises to improve production efficiency and reduce operating costs.

With the continuous development of the packaging industry, people’s requirements for packaging are getting higher and higher. In order to meet market demand, improve production efficiency, and reduce costs, High-Resolution Inkjet Printers, as advanced inkjet coding equipment, are gradually being valued and applied by the packaging industry.

Advantages of UV inkjet printers in the packaging industry

1. High-speed coding capability:

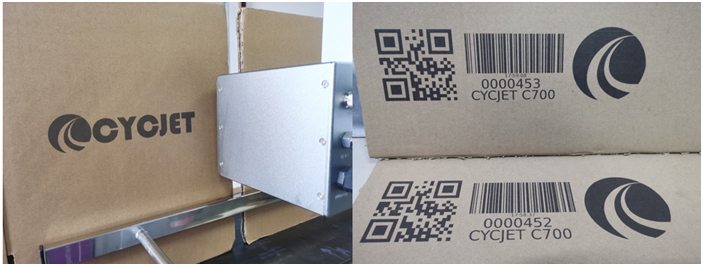

The UV inkjet printer uses high-speed inkjet technology to achieve fast and high-quality coding on the surface of packaging. Compared with traditional inkjet coding equipment, the Large-Character Inkjet Printer has a higher coding speed and higher precision, effectively improving production efficiency.

2. Wide applicability:

According to different packaging materials, the UV inkjet printer can flexibly adjust the coding parameters to adapt to different types of packaging products. Whether it is plastic packaging bags, cartons, aluminum-plastic composite packaging, or glass bottles, the UV inkjet printer can achieve clear and durable coding effects.

3. Environmental protection and energy saving:

The UV inkjet printer uses ultraviolet curing technology. The ink is instantly cured after coding, and no additional heating equipment is required. Compared with traditional inkjet coding equipment that consumes a lot of energy for heating and drying, the Inkjet Coding Machine is more energy-saving and environmentally friendly, which conforms to the sustainable development concept of modern industry.

In summary, the application of UV inkjet printers in the packaging industry plays an important role in ensuring product quality, combating counterfeiting, and improving brand credibility. By providing clear and reliable identification for products and improving consumers’ trust in brands, Inkjet printing Machines provide strong support for the development and promotion of the packaging industry.

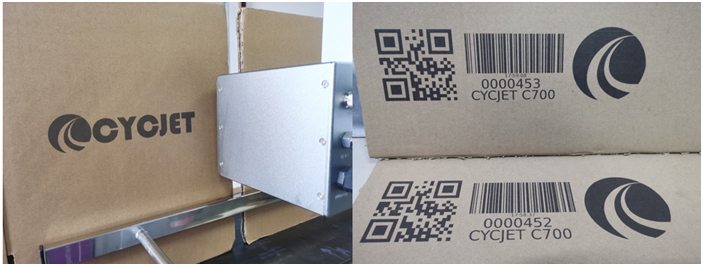

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than 20 years of experience for R&D of different types of handheld inkjet printing solutions, laser printing solutions, portable marking solutions, and high-resolution printing solutions in Shanghai, China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://www.youtube.com/shorts/gXxqmp7EJFE

Facebook: https://www.facebook.com/100064098422560/videos/496303399534085

Linkedin: https://www.linkedin.com/company/31398835/admin/dashboard/