As a metal material with excellent performance, stainless steel has been widely used in the consumer electronics industry due to its corrosion resistance, high strength, and aesthetics. From the shell of smartphones to the metal parts of laptops to the frames of various small electronic devices, the use of stainless steel not only improves the durability of the product, but also gives the product a unique texture and appearance. However, with the rapid development of the consumer electronics industry, the requirements for stainless steel surface marking technology are also getting higher and higher, which has led to the emergence of Fiber Laser Marking Machines, which have quickly become the industry’s preferred solution.

The role of Stainless Steel Laser Coding Machines is mainly reflected in product identification, traceability, and anti-counterfeiting. In the production process of consumer electronic products, each component needs to be accurately marked to facilitate tracking of production batches, quality inspection, and after-sales service. Traditional coding methods, such as inkjet printing or mechanical engraving, often have problems such as easy wear of marks, high consumable costs, and being unfriendly to the environment. In contrast, laser marking machines, with their high efficiency, environmental protection, and durability, have brought a new solution to the industry.

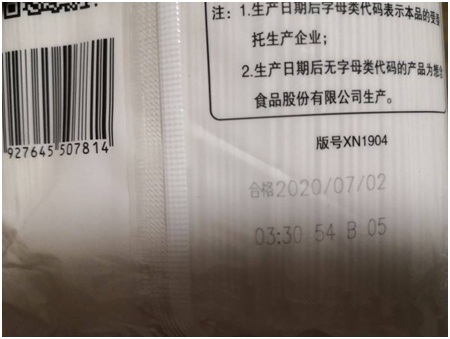

The core principle of the laser marking machine is to use a high-energy-density laser beam to focus on the surface of stainless steel. By precisely controlling the energy, pulse width and scanning path of the laser, high-definition and high-precision marks can be formed on the surface of stainless steel, including text, patterns, QR codes, etc.

The advantages of this technology are obvious. First, laser coding can form extremely fine marks on the surface of stainless steel with an accuracy of up to micrometer level. This means that even in a limited space, a large amount of information can be clearly marked, meeting the requirements of miniaturization and high integration of consumer electronic products. Secondly, the marks formed by Stationary Laser Marking Machines are extremely durable. Since the marks are formed through physical and chemical changes in the material, they will not easily wear or fade due to friction, high temperature, or chemical corrosion and can remain clearly identifiable for a long time. This is crucial for product traceability and quality tracking.

In addition, laser marking machines also have significant environmental and cost advantages. Laser coding does not require any consumables, and no harmful substances are produced during the processing, which fully meets the environmental protection requirements of the modern consumer electronics industry. At the same time, since there is no need for consumables and the subsequent maintenance costs are reduced, laser marking machines can significantly reduce the production costs of enterprises in the long term.

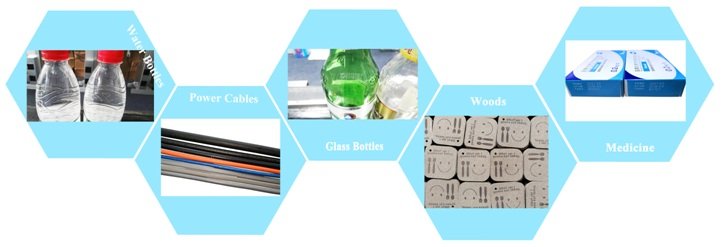

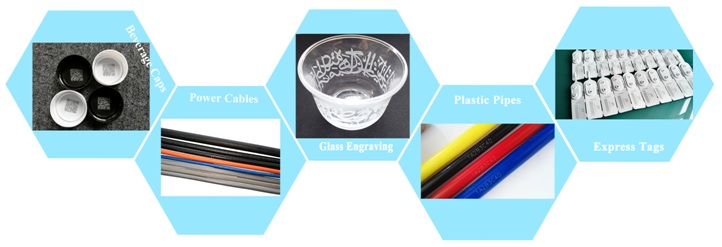

In practical applications, stainless steel laser marking machines have been widely used in the production of consumer electronic products. For example, in the production of smart phones, laser coding can be used to mark the model, serial number, QR code, and other information of the mobile phone shell; in the production of laptops, laser coding can be used to mark the keyboard, heat dissipation holes, and other components. These marks are not only beautiful but also can effectively improve the quality and recognition of the product.

In short, Portable Desktop Laser Marking Machines are becoming an indispensable surface marking technology in the consumer electronics industry with their advantages of high precision, high durability, and environmental protection. With the continuous advancement of technology and the further expansion of applications, laser marking machines will show their strong value in more fields and provide strong support for the production and development of consumer electronic products.

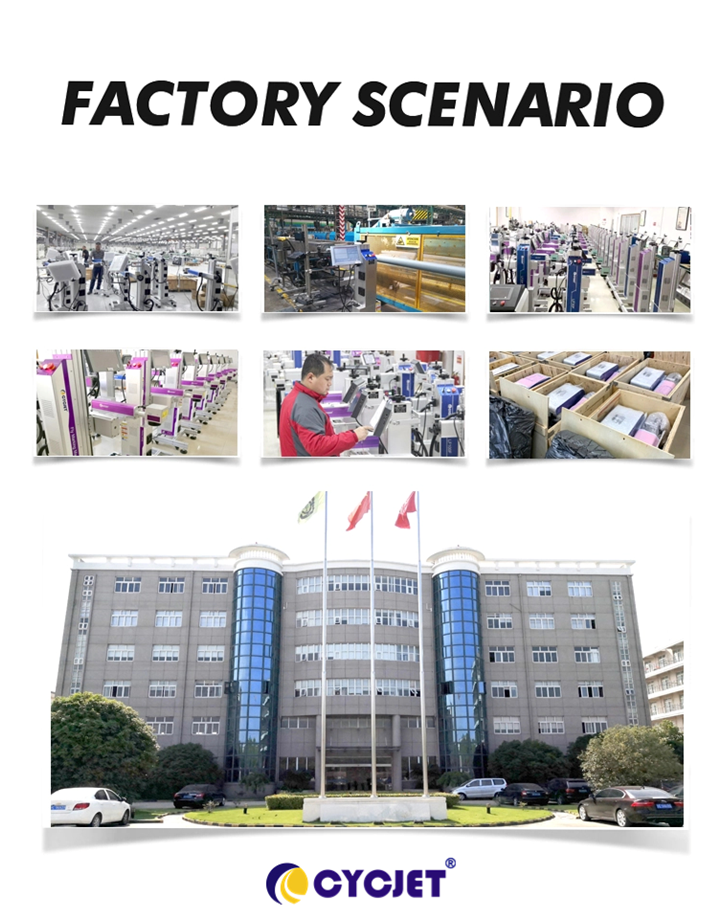

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than 20 years of experience for R&D of different types of handheld inkjet printing solutions, laser printing solutions, portable marking solutions, and high-resolution printing solutions in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://www.youtube.com/watch?v=BCgbd-bxavo

Facebook: https://www.facebook.com/100064098422560/videos/1799130023818781

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:6993870550787923968

Tiktok: https://www.tiktok.com/t/ZTR7Qdtyn/