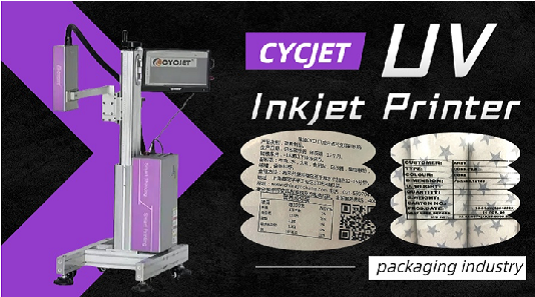

With the continuous development of technology, why are more and more companies choosing to use UV inkjet printers today? What benefits can it bring to businesses? What are the advantages? Let’s take a look at it today.

The principle of UV inkjet printer:

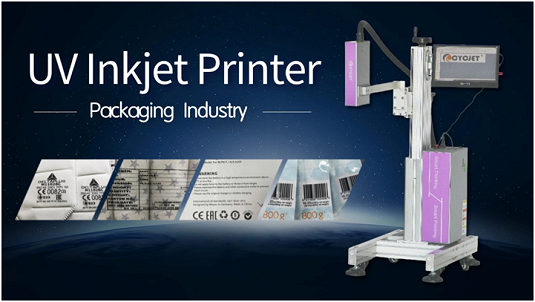

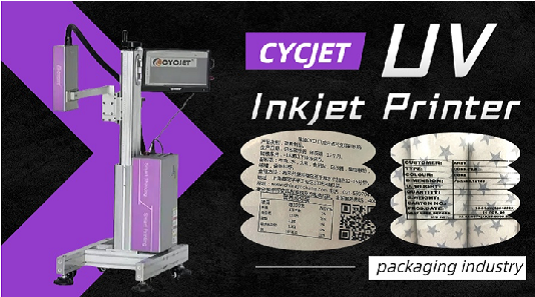

Industrial Inkjet Printers use UV LED lights to dry or cure ink during the printing process. Install UV light source on the conveyor table. The LED light source reacts with the photo initiator in the ink, causing it to instantly dry and adhere immediately to the substrate. Through instant curing, UV inkjet printers can print realistic graphics on a variety of material surfaces, including products such as plastic, glass and metal.

The advantages of UV inkjet printers are:

1. Safer:

Unlike solvent inks, true UV inks emit virtually no volatile organic compounds (VOCs), making this printing process very environmentally friendly.

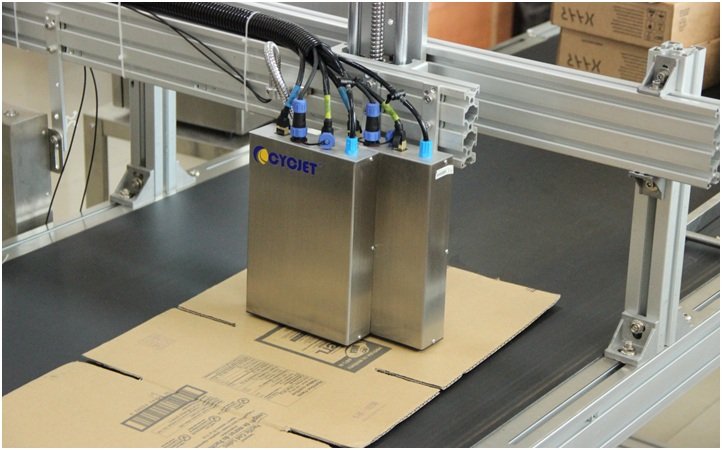

2. Faster production speed:

Online Inkjet Printers use UV inks that cure instantly, so there is no need to shut down before completion. The process requires less labor than other inkjet marking technologies and allows you to get more done in less time.

3. Higher durability:

UV-curable inks are more resistant to damage such as scuffs and marks.

4. More refined:

UV curable ink prints more clearly than using transfer printing methods.

5. Lower cost:

Large Character Inkjet Printers can save costs because no additional materials are usually required during finishing or installation, and the additional protection of the laminate may not be needed at all, by printing directly onto the substrate, you end up using less material, saving time and labor.

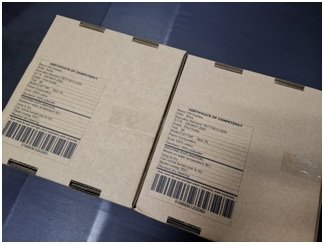

UV inkjet printers can be mainly used in food and beverages, cartons, medicine, building materials, pipes, electronics, hardware, daily chemicals, logistics and other fields. In many industries, the tracking and traceability requirements for products are very strict, and the High-Resolution Inkjet Printer system can inkjet codes on products and record production dates, production batches, logistics information, etc. In this way, during the product circulation and consumption process, consumers can understand the production and circulation status of the product by scanning the inkjet code information to ensure the safety and quality of the product.

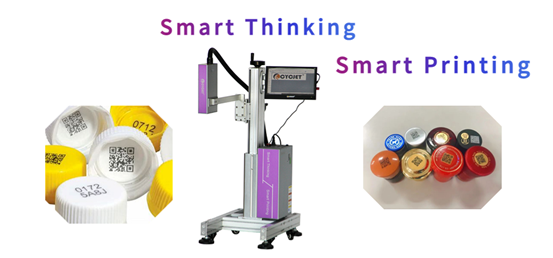

At the same time, with the continuous advancement of technology, UV inkjet printers have made great progress in terms of content complexity, printing speed, resolution, printing color, etc. In terms of content complexity, from simple text information to complex variable personality graphics, variable QR codes, quantum cloud codes, etc., Inkjet Printing Machine can achieve it. This improvement in capabilities provides companies with more creativity and flexibility, making product packaging more beautiful, better conveying product features and achieving product traceability.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video:https://youtu.be/E3ThTfjiYgY

Facebook:https://www.facebook.com/100064098422560/videos/2352953298223673

Tiktok:https://www.tiktok.com/@highresolutioninkprinter/video/7127836075653106990

Linkedin:https://www.linkedin.com/feed/update/urn:li:activity:7127838086243225600