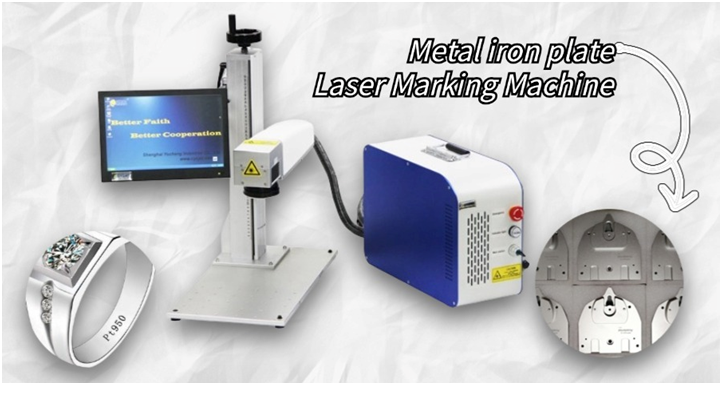

In the jewelry industry, the application of Fiber Laser Marking Machines is becoming more and more widespread. Its efficient, accurate and clear printing technology has brought revolutionary changes to jewelry production. Fiber laser marking machines not only improve production efficiency, but also enhance product traceability and anti-counterfeiting, becoming an indispensable and important equipment in jewelry production.

- Overview of the application of fiber laser marking machine in the jewelry industry

As an important part of the fashion industry, the jewelry industry has a wide variety of products, including gold and silver jewelry, jewelry and jade, fashion accessories, etc. In the jewelry production process, Fiber Laser Printers are mainly used to print information such as production date, batch number, brand logo, anti-counterfeiting code, etc. on the jewelry. This information is of great significance for product traceability, anti-counterfeiting and brand building.

- Application advantages of fiber laser marking machine in the jewelry industry

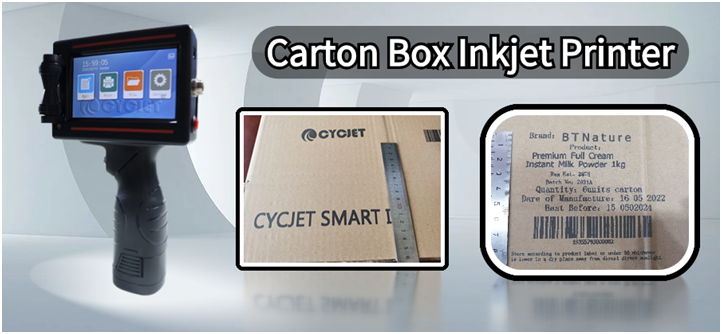

- Improve production efficiency: The fiber laser marking machine adopts automated printing technology, which can quickly and accurately complete the printing task, greatly improving production efficiency. In jewelry production, the inkjet printer can quickly print a large number of ornaments, reduce manual operation time, and reduce production costs.

- Enhance product traceability: The production date, batch number and other information printed by The fiber Laser Marking equipment can be used to trace the jewelry. Once a quality problem occurs or a product recall is required, the problem batch can be quickly located to reduce losses.

- Enhance product anti-counterfeiting: The anti-counterfeiting code printed by the laser marking machine is unique and can effectively prevent the product from being copied and misused. In the jewelry industry, the anti-counterfeiting code is of great significance for protecting brand reputation and consumer rights.

- Enhance brand image: Brand logos, LOGO and other information printed by laser marking machines can enhance the brand recognition of products and enhance brand image. In the fierce market competition, brand image building is crucial for jewelry companies.

- Specific application cases of laser marking machines in the jewelry industry

- Printing of gold and silver jewelry: In the production of gold and silver jewelry, laser marking machines can print information such as production date, brand logo, purity, etc. This information is of great significance for consumers to understand product attributes and make purchasing decisions. At the same time, Laser Coding Printers can also print anti-counterfeiting codes to protect brand rights.

- Jewelry and jade printing: Jewelry and jade are high-value commodities, and their authenticity and quality are the most concerned issues for consumers. Laser marking machines can print information such as origin, quality grade, and identification certificate number on jewelry and jade, providing consumers with authoritative identification basis. At the same time, laser marking machines can also print anti-counterfeiting codes to ensure the authenticity of the product.

- Printing of fashion accessories: As fast-moving consumer goods, fashion accessories are updated very quickly. Laser marking machines can quickly print information such as production date and batch number to help manufacturers achieve product traceability management. At the same time, Laser marking machines can also print brand logos, LOGOs and other information to enhance brand image and recognition.

- Future development trend of laser marking machine in the jewelry industry

With the continuous development of science and technology, laser marking machine technology is also constantly improving. In the future, laser marking machines will be more intelligent, efficient and precise. For example, laser marking machines can automatically identify different types and sizes of jewelry, automatically adjust printing parameters, and achieve precise printing. At the same time, laser marking machines can also be combined with technologies such as the Internet of Things and big data to achieve real-time collection, transmission and analysis of product information, providing a more intelligent solution for jewelry production.

In short, the application of Portable Desktop Laser Marking machines in the jewelry industry has broad prospects and potential. With the continuous advancement of technology and the continuous expansion of application scenarios, laser marking machines will bring more convenience and value to jewelry production.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtu.be/B83rm_e7CZ8

Facebook: https://www.facebook.com/100064098422560/videos/1799130023818781

LinkedIn: https://www.linkedin.com/feed/update/urn:li:activity:6993870550787923968