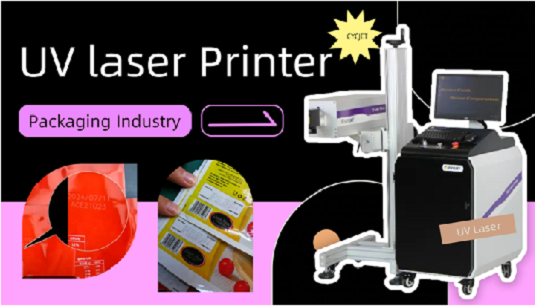

With the development of science and technology, UV Laser Marking equipment’s have become an essential tool in the field of modern industrial identification. With its unique advantages, laser marking machines provide high-precision and high-efficiency identification solutions for many industries.

With the advent of Industry 4.0, intelligent manufacturing and personalized customization have become trends. Laser marking machines, with their high precision and high efficiency, provide strong technical support for modern industry. In the manufacturing industry, laser marking machines can not only realize product identification, but also add unique artistic effects to products and increase the added value of products. In addition, laser marking machines also play an important role in logistics, medical care, food and other fields.

一、Application fields of laser marking machines

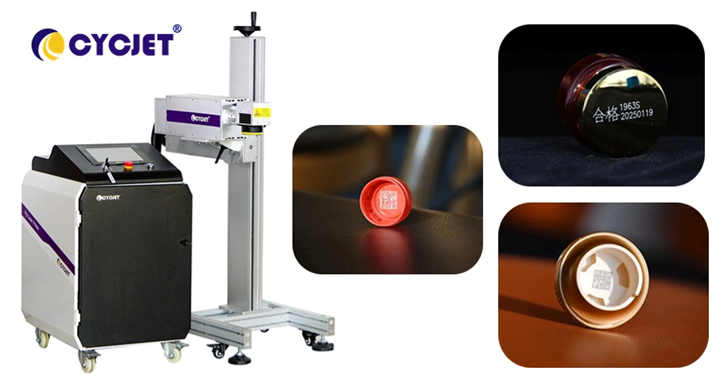

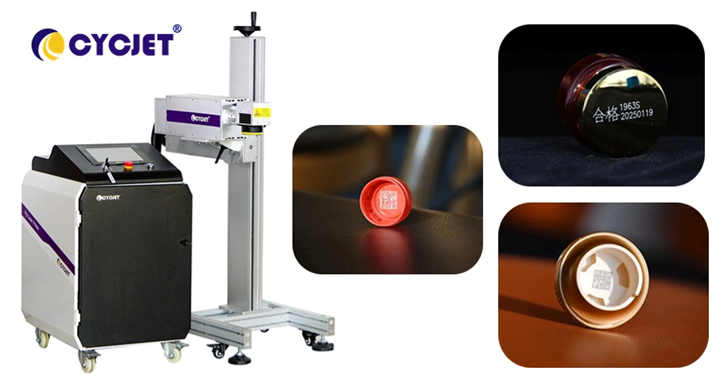

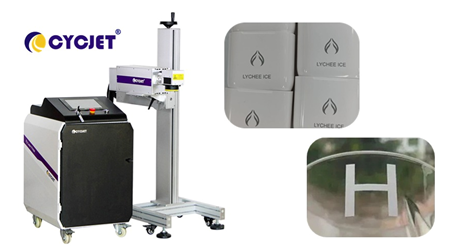

1. Metal products: Metal materials are widely used in many fields due to their unique physical properties and aesthetic effects. Laser Coding Machines can quickly and accurately mark various patterns, texts and other information, making the products more unique and exquisite.

2. Plastic products: When marking on plastic products, the high precision and high efficiency of the laser marking machine make the marking of plastic products clearer and more durable. In addition, laser marking can also change the color of plastics, making the products more distinctive.

3. Electronic products: In the field of electronic products, UV Laser Printers are mainly used to mark circuit boards, electronic components, etc. Its high-precision engraving effect can meet the requirements of electronic products for details.

二、 Advantages of laser marking machine

1. High precision: The laser marking machine has extremely high precision and can achieve micron-level engraving, meeting the needs of various fine markings.

2. High efficiency: The laser marking machine uses high-energy laser beams for engraving, which greatly improves work efficiency and reduces production costs.

3. Strong applicability: The High-Speed Laser Marking machine can be applied to various materials and fields and has high versatility.

4. Environmentally friendly and pollution-free: There is no chemical substance involved in the laser marking process, and no harmful substances will be produced, which meets environmental protection requirements.

In short, Flying Laser Marking Machines have become an essential tool in the field of modern industrial identification with their advantages of high precision, high efficiency, environmental protection and pollution-free. With the continuous advancement of science and technology, laser marking machines will play a greater role in more fields and provide a strong impetus for the development of modern industry.

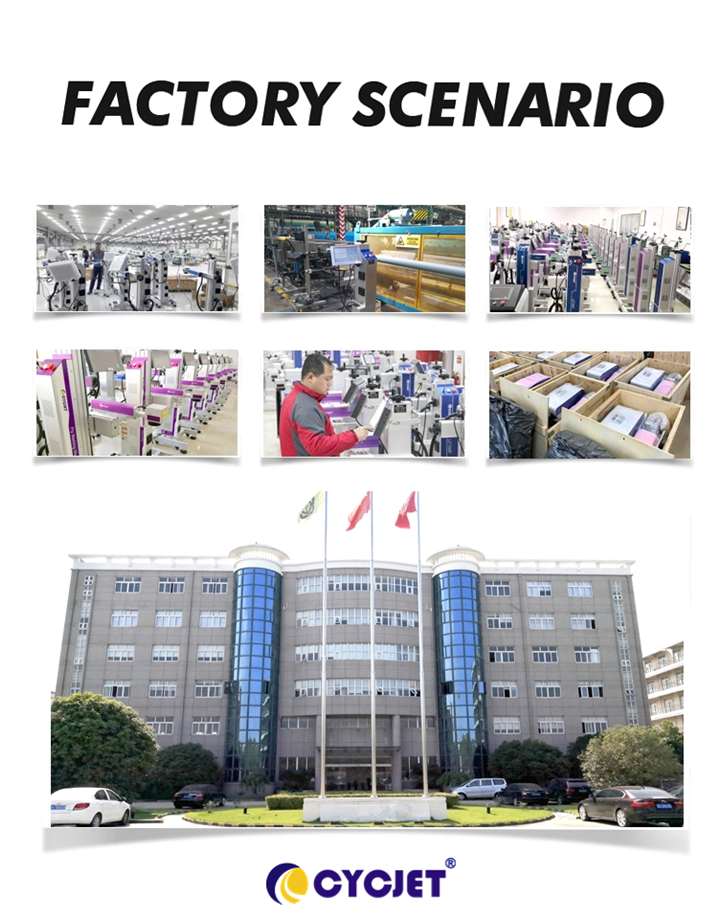

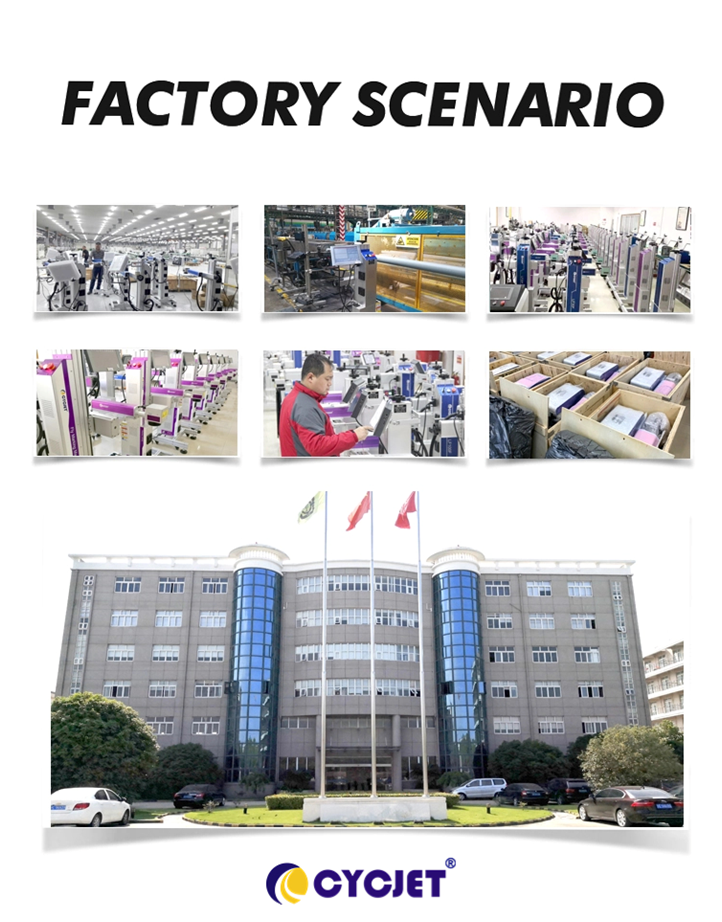

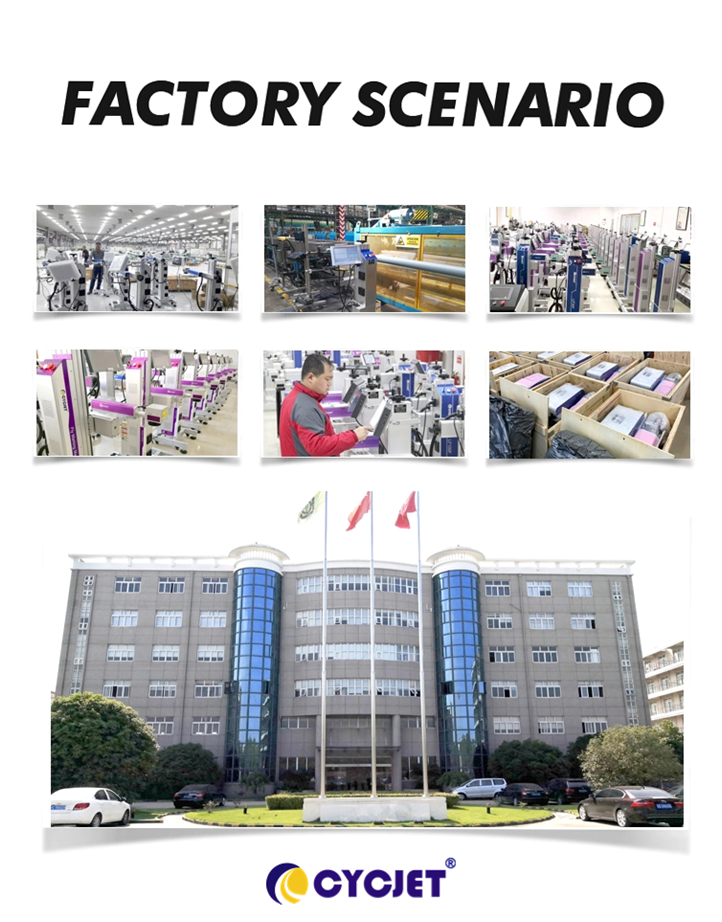

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtu.be/keNsWc_lauo

Facebook: https://www.facebook.com/100064098422560/videos/644076704472578

LinkedIn: https://www.linkedin.com/feed/update/urn:li:activity:7131097748744912896