In daily life, we see many plastic products, such as home appliance housings, auto parts, cosmetic packaging, etc., which are sprayed with a layer of powder on the surface, which is not only beautiful but also protects the product from damage. However, how to make clear and lasting marking on the surface of these powder layers?

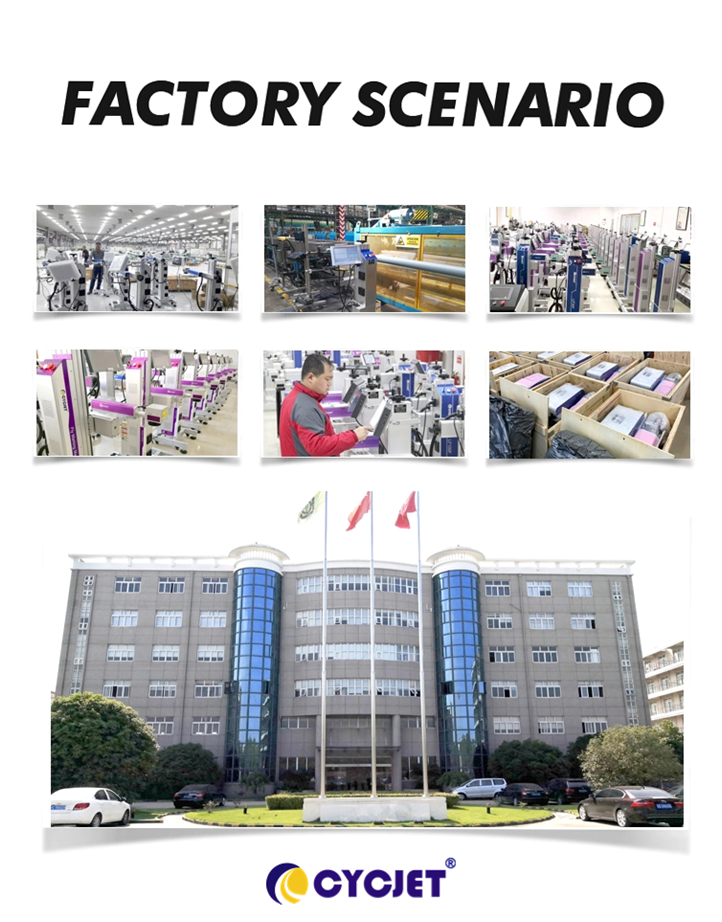

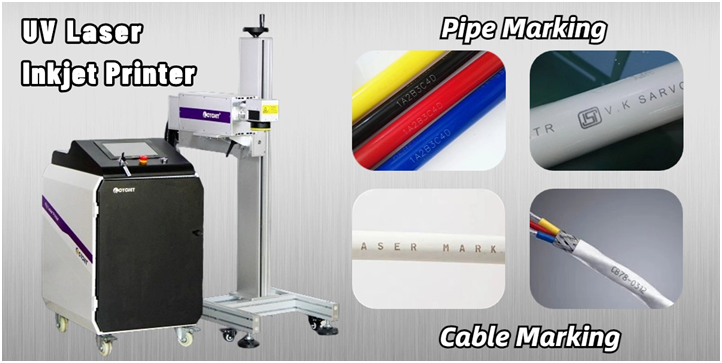

Traditional marking methods, such as inkjet printing and mechanical engraving, are not only inefficient, but also easy to leave marks on the surface of plastic products. The ink marks on plastic products are easy to fade, and the ink printing cannot peel off the spray coating for marking. Mechanical pressure may also penetrate the surface layer under the powder coating, causing material deformation and damage, etc., affecting the appearance and service life of the product. The technology of UV Laser Marking Machine has become an ideal choice for surface treatment of plastic products with its unique advantages.

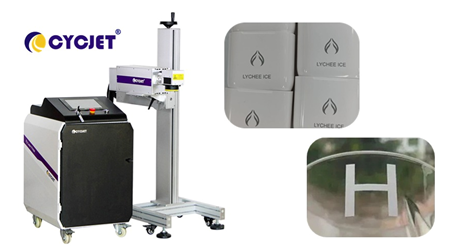

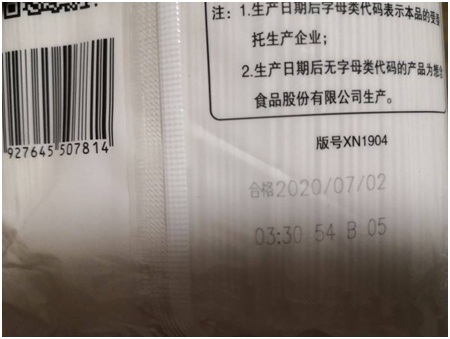

The laser beam can accurately control the size, position and depth of the mark, making the mark clearly visible and not easily worn or blurred, and removing the spray coating cleanly and clearly without damaging the surface of the plastic body. This is undoubtedly an important advantage for plastic products that need to be stored and used for a long time.

High-Speed Laser Marking Machines also have good adaptability and flexibility in the application of marking on the surface of spray powder layer of plastic products. Different plastic product surfaces may have different spray powder layer materials and thicknesses, and the marking machine can adapt to different marking requirements by adjusting the laser parameters. This makes laser marking equipment a very versatile and practical marking tool.

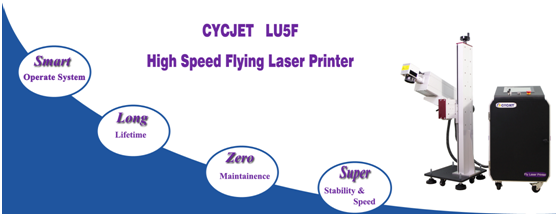

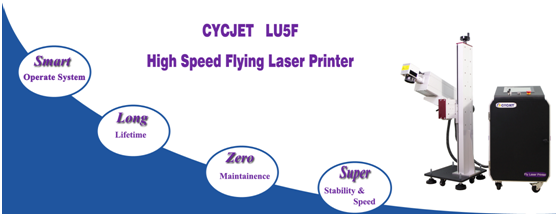

Laser marking machines can complete a lot of work in a short time. This not only improves production efficiency, but also reduces production costs. Its marking speed can reach 14000mm/s. In order to improve production efficiency, laser marking equipment can be combined with production lines for unmanned automatic marking, automatically positioning plastic products without manual placement. Non-stop marking helps companies increase production capacity and reduce labor cost output.

In summary, flying Laser Marking Machines have the characteristics of high speed, high precision and high definition, and can form lasting and clear marks on the surface of plastic products. In addition, laser marking technology can also achieve personalized customization and add added value to plastic products.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video:https://youtu.be/CRhvvZ7j0Dg

Facebook:https://www.facebook.com/100064098422560/videos/2357166871128471

Linkedin:https://www.linkedin.com/feed/update/urn:li:activity:7028978282092007424