In the automotive manufacturing industry, Laser Marking Machines have become indispensable precision engravers. With its high precision, high efficiency and high stability, it provides strong support for every link of automotive manufacturing.

In the automotive sector, components need to be fully traceable, not only for safety reasons, but also for technical reasons. Car manufacturers use unique, counterfeit-proof and easy-to-read Data Matrix codes and alphanumeric inscriptions in their vehicles. Laser marking machines are used to engrave these important codes on almost any material, regardless of whether the component is made of plastic or metal.

一、Unique advantages of laser marking machines

Portable Laser Marking Machines use high-energy-density laser beams to engrave and mark automotive parts. This process has incomparable advantages over traditional mechanical engraving.

- High precision: The laser marking machine has extremely high precision and can accurately engrave and mark parts at the micron level, ensuring the accuracy and quality of the product.

- High efficiency: The Laser Coding Machine has extremely high working efficiency and can complete a large number of processing tasks in a short time, greatly improving production efficiency.

- High stability: The working process of the laser marking machine is stable and can work continuously for a long time, reducing production interruptions caused by equipment failure.

Since laser marking is also resistant to thermal stress and exposure to acids, gasoline, oil and heat, maximum traceability of the quality of each component is permanently guaranteed. Laser marking is also economical due to its ease of use and high speed.

二、 Application of laser marking machine in automobile manufacturing industry

- Parts marking: Mini laser marking machine can accurately mark automobile parts, including part number, production date, brand and other information. This information is very important for product traceability and management.

- Pattern engraving: Laser marking machine can also engrave complex patterns on the surface of automobile parts, such as car logos, car emblems, etc., to make the product more personalized.

- Special process: For some parts made of special materials, such as stainless steel, aluminum alloy, etc. Handheld Laser Marking Machine can perform high-precision cutting and engraving, adding more possibilities to the product.

The laser marking machine has the characteristics of high speed and high precision. It can complete the QR code marking work on a large number of iron sheets in a short time, greatly improving production efficiency.

With the continuous advancement of science and technology, the performance and functions of laser marking machines will continue to improve. With its high precision, high efficiency and high stability, it provides strong support for every link of automobile manufacturing. In the future, laser marking machines will be more intelligent and automated, and can better meet the needs of the automobile manufacturing industry. At the same time, as the concept of environmental protection is deeply rooted in people’s hearts, the green environmental protection performance of laser marking machines will also receive more attention.

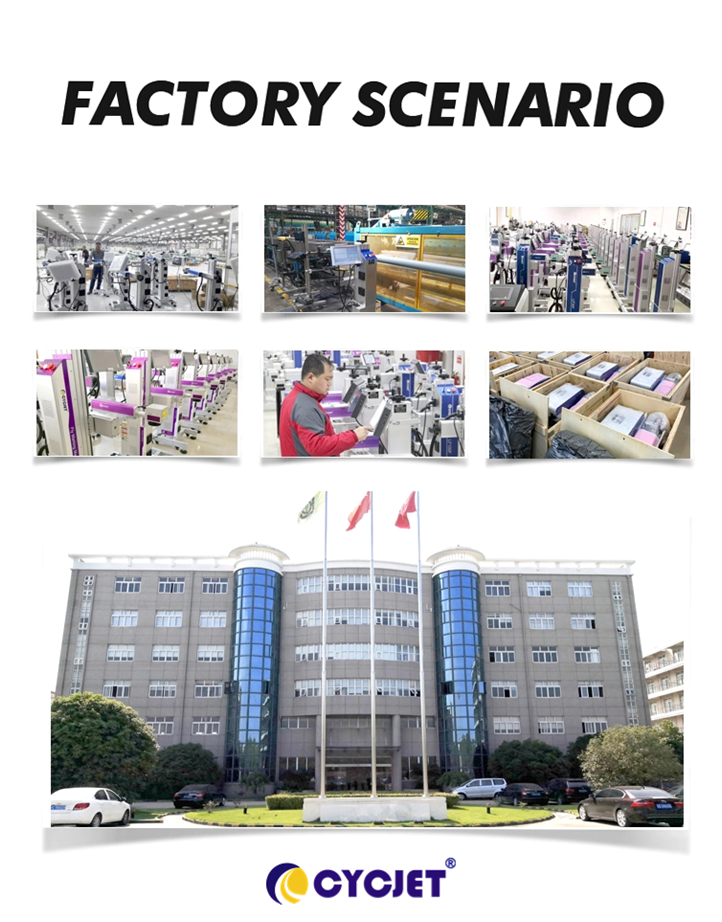

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video:https://www.youtube.com/shorts/8Wzezpu6r2Y

Facebook:https://www.facebook.com/100064098422560/videos/281917381469623

Tiktok:https://www.tiktok.com/@cycjetlasermarker/video/7303801931032562975

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:7132547291265019905