The demand for auto parts in the market is growing day by day, which also makes many related production machines familiar to people, and laser marking machine is one of them. Handheld laser marking machines are often used to engrave logos on metal, plastics, glass, semiconductors and other products. Nowadays, their application in auto parts has become a trend. The application of this technology not only improves production efficiency, but also brings better solutions to the marking of auto parts.

The Hand Coding Machine is a high-precision and efficient processing equipment that uses laser beams to engrave and mark the surface of the material. Compared with traditional mechanical engraving and inkjet printing marks, laser marking machines have higher mark quality and durability. It can quickly and accurately complete various complex marking tasks on the surface of auto parts without causing damage to the material surface.

Applying Handheld Laser Coding Machines to auto parts can achieve various types of markings. For example, it can be used to mark car parts with serial numbers, production dates, manufacturer logos, QR codes and other information. These marks not only help with quality control and anti-counterfeiting traceability during the production process, but also help users identify and repair cars.

In addition, Hand Marking Machines can also be used to create high-precision patterns and patterns on auto parts. These patterns not only enhance the aesthetics of the product, but can also be used for product branding and market differentiation. For example, automobile manufacturers can engrave unique patterns on hoods, doors and other parts to display their brand image and personalized customization services. It can also peel paint off the surface of large automobile parts. The peeling effect is clean, beautiful and efficient.

The application of mini laser printer on auto parts also has environmental protection advantages. While traditional mechanical marking and inkjet marking methods create waste and pollution, laser marking machines do not have these negative impacts. It is a non-contact processing method that does not produce noise and pollution, while also saving raw materials and reducing energy consumption.

In short, the application of Laser Marking Machines on auto parts is an innovative solution. It can not only improve production efficiency and quality, but also provide high-precision, high-definition logo and pattern production, ink translucent paint stripping, etc. With the continuous advancement of technology and the expansion of application fields, it is believed that the application of laser marking machines in auto parts will become more and more widespread.

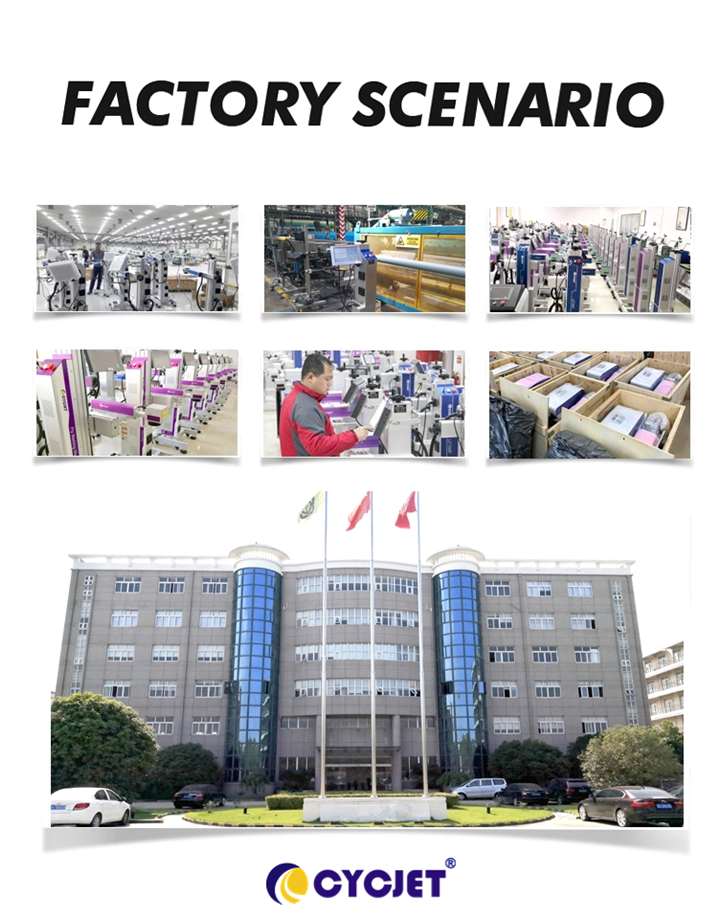

Laser Marking MachineCYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB: +86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://www.youtube.com/shorts/5TyU-ZtuPVU

Facebook: https://www.facebook.com/100064098422560/videos/948637053038254

LinkedIn: https://www.linkedin.com/feed/update/urn:li:activity:7176045067382489089