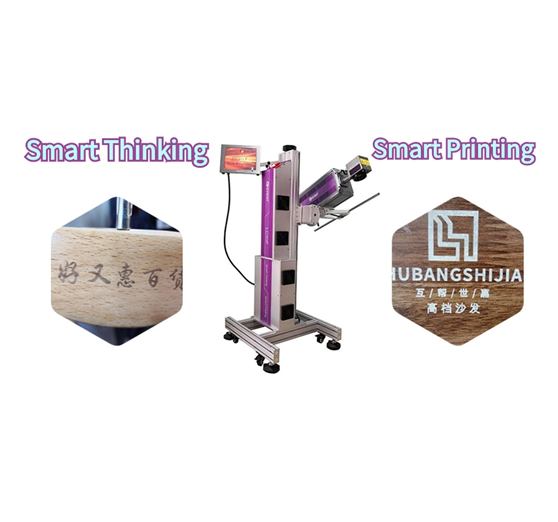

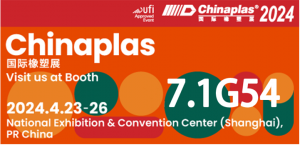

Exhibition date: April 23-26, 2024 (09:30-17:00)

Exhibition Venue: Shanghai National Convention and Exhibition Center (Hongqiao), China

[No. 333, Songze Avenue, Qingpu District, Shanghai, China]

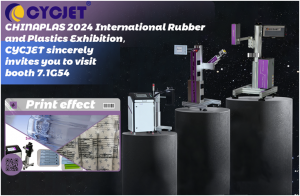

Booth number: 7.1G54

As an important participant in the industry, CYCJET-Yuchang Industrial actively responds to market trends and will attend the CHINAPLAS International Rubber and Plastics Exhibition for the fifth consecutive year. CHINAPLAS International Rubber and Plastics Exhibition, as the most influential rubber and plastics industry event in Asia, has been committed to promoting the innovation and development of the rubber and plastics industry. This exhibition will be held grandly at the Shanghai Hongqiao National Convention and Exhibition Center from April 23 to 26, 2024. At that time, CYCJET-Yuchang Industrial will also bring cutting-edge Laser Marking Machine and Inkjet Printer technology and products to the exhibition, discuss the future development direction of the rubber and plastics industry with industry colleagues from all over the world, and create exquisite logos.

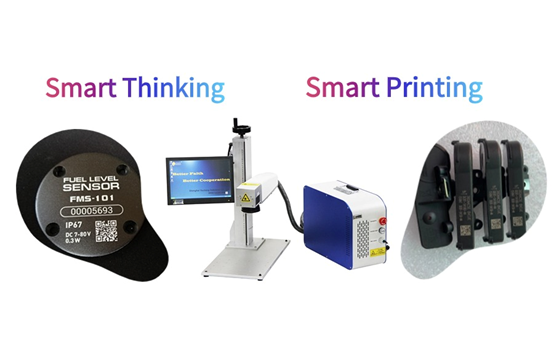

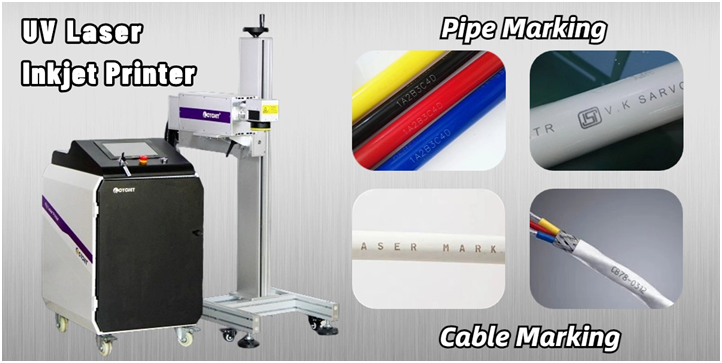

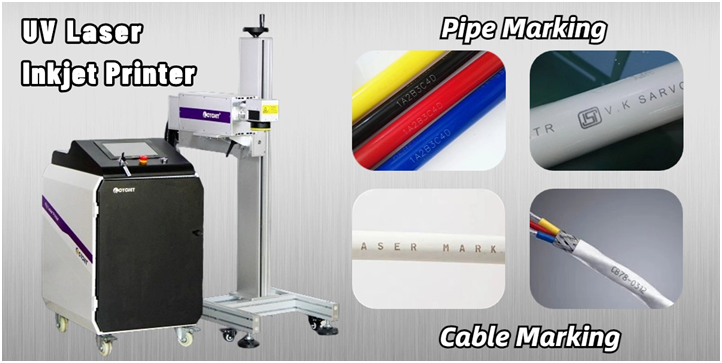

At this rubber and plastics exhibition, our company will display CYCJET series inkjet printers and laser marking machines at the exhibition, such as ALT500UV High-Resolution Inkjet Printer, LF30 Laser Marking Machine, C700i Inkjet Printer, CH702UV Inkjet Printer, portable handheld inkjet printer, etc. the main application directions are film rolls, rulers, batteries, cartons, pipes, beverage bottles, plastic bags, wood, metal, tires, rulers and other materials. Based on the needs of different groups, we create perfect logo solutions for each customer, so that the logo can complement the product. At the same time, we will also use on-site demonstrations and interactive sessions to allow visitors to more intuitively understand the performance of laser printers and the magic of laser marking machines.

CYCJET adheres to the portable marking concept of “Smart Thinking, Smart Printing”, and uses professional technology, first-class quality, humanized service and preferential prices to meet the needs of different users. And work together with new and old customers and friends to develop together, share a win-win situation, experience efficient and convenient logo solutions, and strive to move forward for China’s creation!

From April 23 to 26, 2024 (09:30-17:00), CYCJET sincerely invites you to visit booth 7.1G54 Experience the magic of laser marking machines and inkjet printers in person, gain an in-depth understanding of our technical strength, have in-depth exchanges with our professional team, and explore the infinite possibilities of laser coding machines and inkjet printers together.

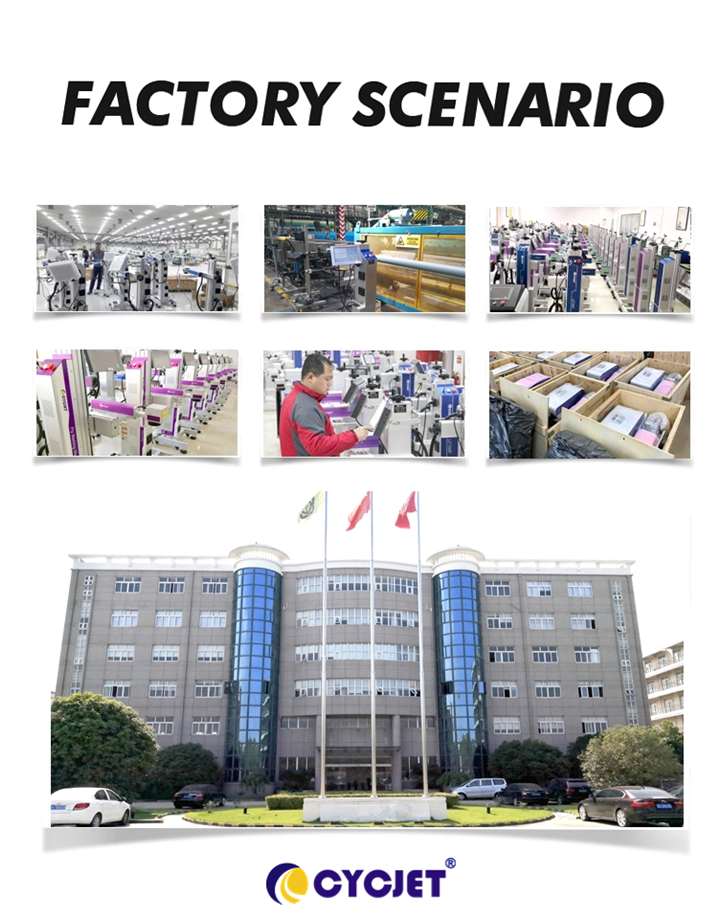

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video:https://youtu.be/ePSM2MSDFUk

Facebook:https://www.facebook.com/100064098422560/videos/1130508061404061

Instagram:https://www.instagram.com/reel/C5SlSH8r2EX/?igsh=MzRlODBiNWFlZA==

Linkedin:https://www.linkedin.com/feed/update/urn:li:activity:7181184491351126017