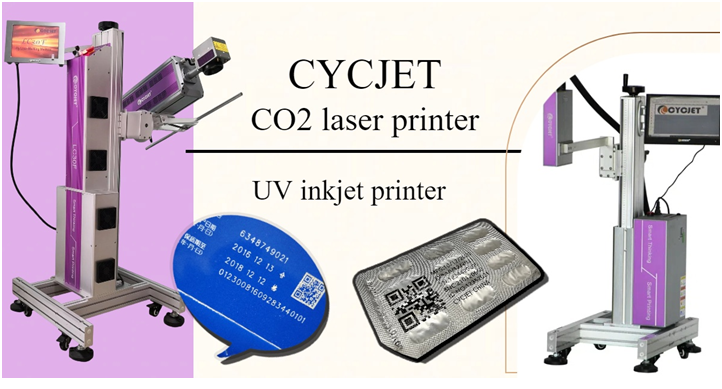

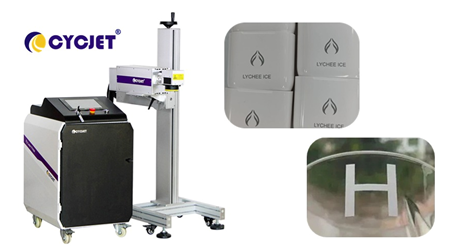

Between the “collision” of laser coding and the demand for beverage production and packaging, we have gradually achieved full coverage of upstream and downstream coding, including whole products and individual products. Whether it is semi-finished product pre-processing coding or finished product labeling manufacturing, laser marking machine technology has been widely used. Including but not limited to common PET plastic, glass and other beverage packaging bottles, such as drinking water, alcohol and other finished product bottle body external labeling, as well as various paper packaging boxes, gift boxes, CYCJET ‘s CO2 Laser Marking Machine can easily handle it.

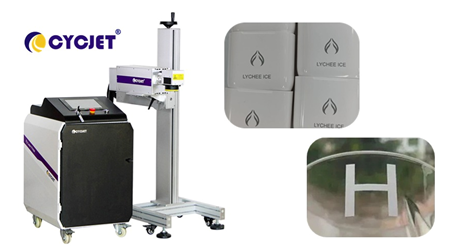

CYCJET laser marking machine adopts advanced laser coding technology, which has the characteristics of high precision, high speed and high reliability. This technical advantage is particularly evident in the beverage production line. The Laser Marking Equipment can quickly and accurately mark the product with clear and lasting marks on the high-speed production line, greatly improving production efficiency and product quality.

Not only that, just for the manufacturing of internal and external code labels for bottled beverage caps, CYCJET also has professional personalized customization solutions, which are suitable for common cap types on the market such as 28/38 caps and butterfly caps; it realizes a fully automated process of automatic loading-cap sorting-coding-inspection-rejection-collection, and its bottle cap laser coding solution can also be extended to various seasoning industry fields

Since laser coding is a non-contact process, the focal distance range requirements are relatively more flexible, making it more compatible with upstream and midstream processing such as beverage labeling and film rolling, with lower production requirements and greatly improved coding efficiency.

Moreover, the CYCJET high-speed Laser Marking Machine series is designed for the easy-tear line processing of roll film packaging materials, allowing laser application technology to bring users a faster and lower-cost option. The advantage of no consumables and the cooperation of self-developed tangent control software; free adjustment of line spacing, density, and aperture, to most extent, not only meets the different production needs of various companies, but also drives the intelligent upgrade of front-end packaging processing.

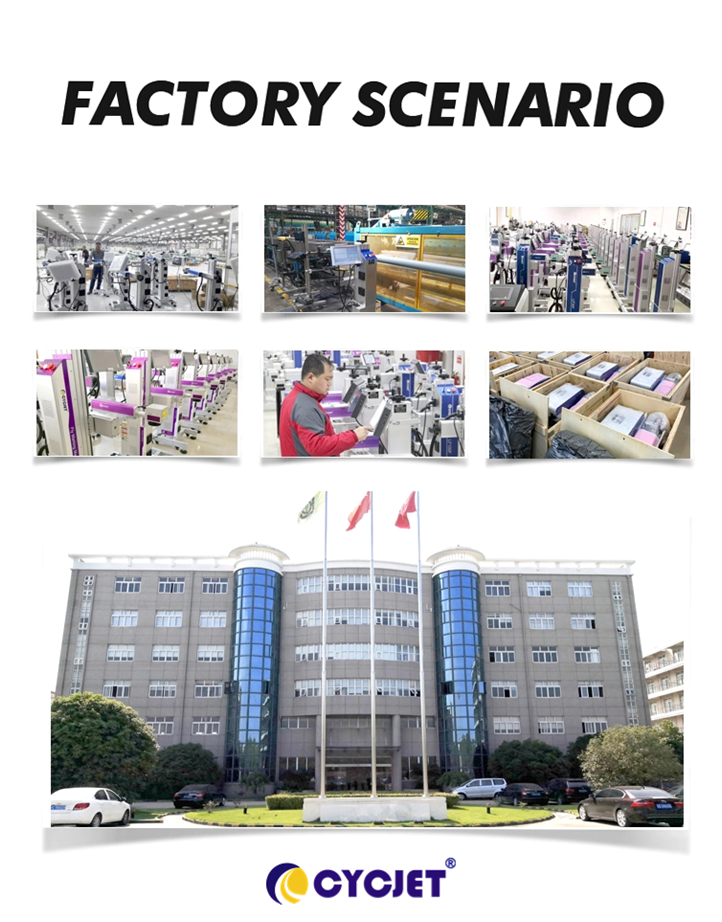

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtube.com/shorts/uF22JAVVu9A?feature=share

Facebook:https://www.facebook.com/100064098422560/videos/267224125615152

Tiktok: http://www.tiktok.com/t/ZTRnyUpBM/

LinkedIn: https://www.linkedin.com/feed/update/urn:li:activity:6945310855408336897