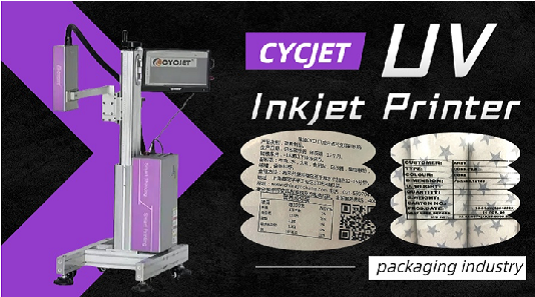

In the food packaging industry, the ingredient list is more than just a simple information label. It carries consumers’ trust in food safety, the company’s commitment to regulatory compliance, and the display of brand image. However, traditional labeling methods, such as thermal transfer and labeling, are often difficult to cope with the complex needs of the industry. The introduction of UV inkjet Printers provides an efficient and accurate solution for printing ingredient lists on food packaging bags, and is becoming a key driving force for industry upgrades.

一、The core pain points of the ingredient list of food packaging bags

1. Difficulty in adapting to multiple materials

Food packaging bags are made of a variety of materials, from plastic films, aluminum foil bags to composite materials. Various materials have different requirements for the adhesion, clarity and durability of labeling technology. Traditional labeling is prone to bubbling or falling off, and thermal transfer printing is difficult to achieve high-quality printing on certain materials.

2. Insufficient environmental adaptability

The environment in which food packaging bags are produced, transported, and stored may involve high temperature, humidity, grease, and other conditions, which poses a challenge to the long-term clarity of the ingredient list. Traditional labeling methods often cannot meet these requirements, resulting in blurred or even missing information.

3. Cost and efficiency issues

Traditional labeling requires consumables and manual maintenance, and is prone to errors, affecting overall production efficiency. For high-volume production companies, how to reduce costs while ensuring efficient operation is a difficult problem that needs to be solved urgently.

4. Regulations and traceability requirements

With the increasingly stringent food safety regulations, the labeling of the ingredient list must not only be clear, but also meet multiple requirements such as anti-counterfeiting, anti-tampering, and traceability. Traditional labeling methods are slightly insufficient in data traceability and flexibility.

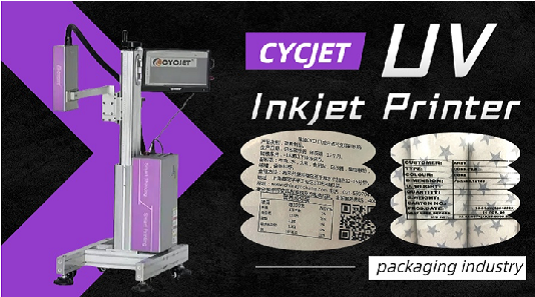

二、 Breakthrough solutions of inkjet printing machines

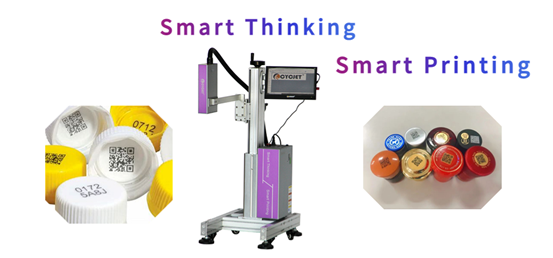

1. Highly adaptable technology

UV inkjet printers use non-contact digital printing technology, which is compatible with a variety of materials. Whether it is soft film or smooth aluminum foil, it can achieve high adhesion and precise printing. No longer worry about material restrictions, allowing companies to flexibly respond to different packaging needs.

2. Durability and environmental protection coexist

The inkjet coding machine uses ultraviolet curing technology to make the printed content dry instantly, and is scratch-resistant, waterproof and oil-resistant. Whether it is refrigerated, transported or displayed on shelves, the printed ingredient list always remains clear, greatly improving the reliability of the product and user experience.

3. High efficiency and low cost

Compared with the labeling method, the UV inkjet printer does not require additional consumables, eliminating the cost of label production and manual operation. The printing speed is fast, supports real-time data changes, and easily achieves high-efficiency production in large quantities.

4. Food safety traceability

The Industrial Inkjet Printer combines industrial 4.0 technology to record production data in real time, accurately associate each bag of product with its production batch, meet the strict requirements of the food industry for safety traceability, and support personalized printing to further enhance brand competitiveness.

三、UV inkjet printers help the food packaging industry to upgrade comprehensively

UV inkjet printers not only solve the pain points in the printing of ingredient lists on food packaging bags, but also bring a new identification mode to the industry: flexible, efficient and environmentally friendly. Its application not only meets the requirements of food safety regulations, but also helps companies reduce costs, improve efficiency, and add points to their brand image.

As consumers continue to pay more attention to food transparency and quality, the food packaging industry is ushering in a revolution centered on labeling technology. Choosing a online inkjet printer is not just choosing a device, but also a step towards the future of food labeling.

In the future, clear labeling is not only a compliance requirement, but also the key to corporate competition. UV inkjet printers create unlimited possibilities for the food packaging industry.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://www.youtube.com/shorts/moqmSGLpZ5A

Facebook: https://www.facebook.com/100064098422560/videos/925705893095267

LinkedIn: https://www.linkedin.com/feed/update/urn:li:activity:7276833905498902528/?actorCompanyId=31398835