High-resolution carton coding technology is an advanced packaging identification technology, which is widely used in food, beverage, daily chemical, electronics, chemical, pharmaceutical and other industries. It is used to print clear and delicate text, graphics, barcodes, QR codes and other information on cartons. The following is a detailed introduction to Large Format Online Inkjet Printer:

1. Technical features

High definition: Using a high-resolution inkjet printer, the resolution can reach 180DPI (dots per inch) or higher, the printing effect is clear and delicate, the edges of text and graphics are smooth and easy to identify.

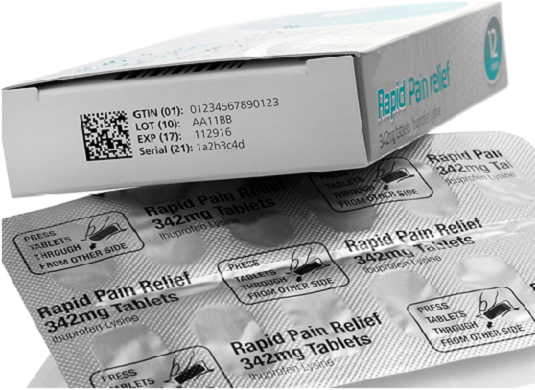

Versatility: Can print a variety of content, including text, numbers, symbols, barcodes, QR codes, graphics, counters, shift codes, time and date, etc.

Supports a variety of fonts, sizes and layout methods to meet the personalized needs of different customers.

Efficiency: The printing speed is fast, reaching tens or even hundreds of meters per minute, suitable for large-scale production lines.

The equipment has good stability and low failure rate, which reduces downtime and improves production efficiency.

Flexibility: Can adapt to different types of cartons, including single-walled cartons, double-walled cartons, standard cartons, etc.

The position and angle of the nozzle can be adjusted according to the size and shape of the carton to achieve precise printing.

Environmental protection: Some high-resolution inkjet printers use environmentally friendly inks to reduce pollution to the environment.

There is no wastewater or exhaust gas emission during the printing process, which meets environmental protection requirements.

2. Application scenarios

Product packaging: Print product name, specifications, production date, shelf life, batch number, barcode, QR code and other information on the carton to facilitate consumer identification and traceability.

Logistics management: Print logistics information on the carton, such as the place of shipment, place of receipt, mode of transportation, cargo status, etc., to improve logistics efficiency and management level.

Brand promotion: Print exquisite brand logos, patterns or slogans on the carton to enhance brand image and product added value.

3. Equipment selection

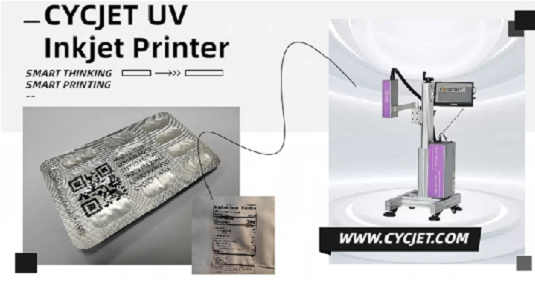

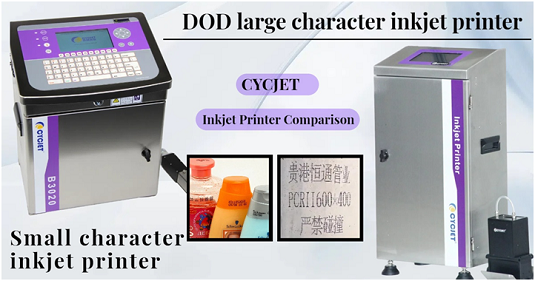

There are many brands and models of high-resolution carton inkjet printers available on the market, such as CYCJETC700 High-Resolution Inkjet Printer, C530UV inkjet printer, ALT500UV large character inkjet printer, etc.

When choosing equipment, the following factors should be considered:

Printing requirements: Choose the appropriate inkjet printer model and configuration according to the product’s printing content, size, shape and speed requirements.

Equipment performance: Investigate the equipment’s resolution, printing speed, stability, failure rate and other indicators, and choose equipment with stable performance and low failure rate.

After-sales service: Choose a supplier with good after-sales service and technical support to ensure that the equipment is maintained and supported in a timely and effective manner during use.

Cost-effectiveness: Comprehensively consider factors such as equipment price, consumables cost, operation and maintenance cost, and choose equipment with high cost performance.

4. Advantages Analysis

Improve recognition: Carton Box Inkjet Printer makes product information, brand logos, etc. easier to identify, and improves the market competitiveness of products.

Enhance brand image: Exquisite inkjet effect can improve the appearance quality of the outer box, enhance brand image and consumer trust.

Easy to trace and manage: By printing barcodes, QR codes and other information, product traceability and management can be achieved, and logistics efficiency and management level can be improved.

Cost saving: High-resolution inkjet printer consumables are low in cost and have good printing effect, which can reduce unnecessary waste and rework and save costs.

In summary, Industrial Inkjet Printer is an efficient, flexible and environmentally friendly packaging identification technology with broad application prospects and market value.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://www.youtube.com/shorts/7zvPITecdM4

LinkedIn: https://www.linkedin.com/feed/update/urn:li:activity:7279334624030273536/?actorCompanyId=31398835

Facebook :https://www.facebook.com/100064098422560/videos/1332905847716513