With the rapid development of the pharmaceutical industry, the requirements for packaging bag marking are also constantly upgrading. In order to meet the comprehensive coverage of the traceability system and strict regulatory standards, UV Inkjet Printers have become an ideal choice for packaging bag marking in the pharmaceutical industry. It not only improves production efficiency, but also significantly improves the clarity and durability of the marking, providing technical guarantee for the safe circulation of medicines.

1. Industry pain points: the problem of clarity and stability of labels

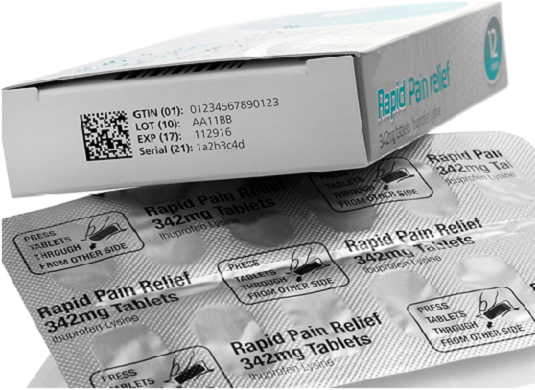

The labels on packaging bags in the pharmaceutical industry usually include key information such as product name, production date, batch number, and medicinal material traceability code. However, traditional labeling methods, such as thermal transfer or labeling, are not only easy to fall off or blur, but also have problems such as high consumables and complex maintenance.

1. Strict traceability requirements: Drug regulatory regulations require that labels be clear, durable and easy to trace.

2. Complex packaging materials: Pharmaceutical industry packaging bags are mostly composite materials with smooth surfaces or moisture-proof coatings, which puts higher requirements on the adhesion of inkjet codes.

3. Production efficiency limitations: Traditional labeling methods are difficult to meet the needs of efficient and stable operations in high-speed assembly lines.

二、Inkjet printing machine: Accurately solve industry pain points

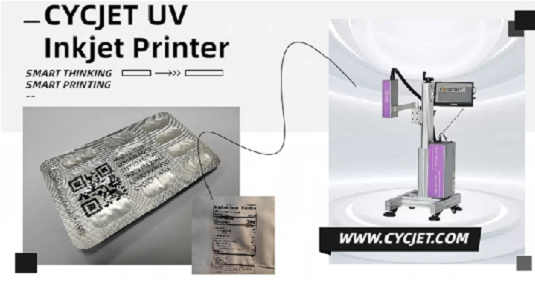

1. Clarity and durability

The UV Inkjet Printer uses specially formulated UV ink to achieve high-adhesion printing effects on composite material surfaces. The content after coding is clear and sharp, and is not affected by moisture and friction, ensuring that the integrity of the logo is maintained for a long time.

2. High-speed printing, compatible with a variety of packaging bag materials

The UV inkjet printer supports high-speed printing operations and is suitable for packaging bags of Chinese herbal medicines of different materials. Whether it is paper, plastic or composite materials, UV ink can cure quickly and achieve instant drying without waiting.

3. Intelligence and traceability

The inkjet coding machine seamlessly connects with the MES system and can generate dynamic QR codes or traceability codes in real time. Each logo on the packaging bag can be associated with the database, which facilitates the traceability management of the product throughout its life cycle. This not only meets the requirements of GMP (Good Manufacturing Practice for Pharmaceuticals), but also enhances consumers’ trust in the brand.

4. Environmentally friendly and efficient, reducing operating costs

Compared with traditional labeling methods, UV inkjet printers do not require additional labels or consumables, significantly reducing material consumption and maintenance costs. At the same time, the environmentally friendly characteristics of UV ink are also in line with the pharmaceutical industry’s advocacy of green production.

三、 How UV inkjet printers promote industry upgrades

In today’s rapidly developing pharmaceutical industry, the application of Industrial Inkjet Printers provides all-round support for enterprises to improve production efficiency, optimize labeling quality, and meet regulatory requirements. It not only solves the pain points of traditional labeling methods, but also sets a new benchmark for the industry through its intelligent and environmentally friendly features.

四、 Choose UV inkjet printer to gain the first-mover advantage in the industry

The labeling quality of packaging bags in the pharmaceutical industry not only affects the market competitiveness of the products, but also directly affects the consumer experience. High-Resolution Inkjet Printers are becoming the best choice for packaging labeling in the pharmaceutical industry due to their high efficiency, accuracy and intelligence. Choose UV inkjet printers to empower your product labeling and keep your company ahead in the competition!

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtu.be/Z1PKe40KJWs

Facebook: https://www.facebook.com/100064098422560/videos/528467522185974

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:6998938005549842432