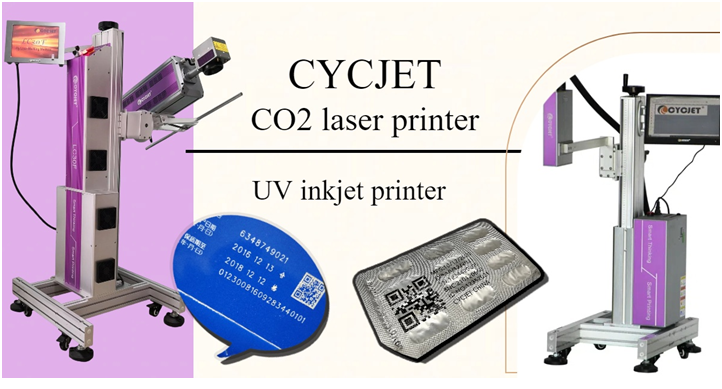

With the continuous advancement of science and technology, the application of laser technology in the industrial field is becoming more and more extensive. Among them, the UV laser Marking Machine, as a high-precision and high-efficiency marking equipment, has shown great potential and value in the cable manufacturing industry.

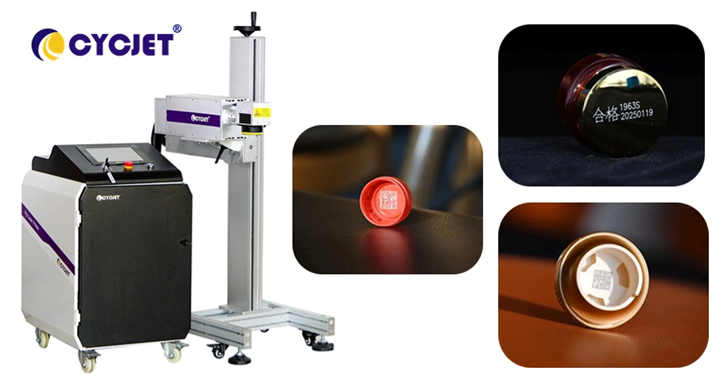

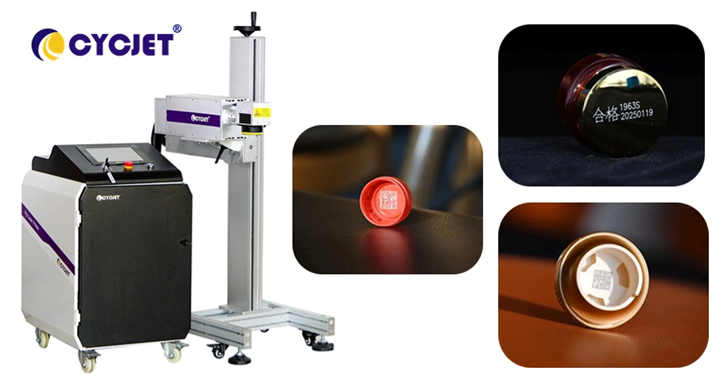

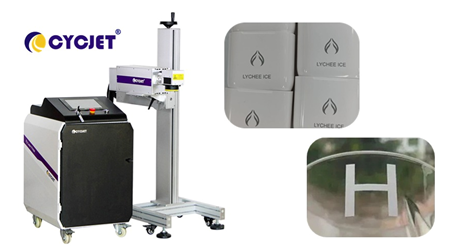

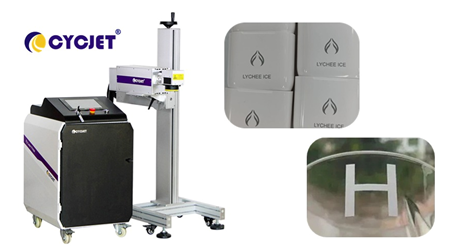

The UV flying laser marking machine uses a 355nm wavelength UV laser as the light source, and directly breaks the molecular chain of the material through the short-wavelength laser, thereby forming a clear and lasting mark on the surface of the material. This cold processing method avoids the problems of large heat-affected zone and material deformation caused by traditional hot processing, and is particularly suitable for marking thin and fragile items such as cables.

- Advantages of UV laser marking machine in cable industry

High precision and high definition

The laser coding machine can quickly mark cables with sub-millimeter accuracy, ensuring that the marking content is clear and easy to read. Whether it is numbers, letters, symbols or complex patterns such as QR codes, it can achieve accurate and correct marking, meeting the high requirements of cable manufacturers for identification quality.

High efficiency and automation

Online marking can be realized on the assembly line, and it can mark in real time according to the moving speed of the cable, which greatly improves production efficiency. At the same time, it can also be seamlessly connected with the industrial automation system to realize dynamic data input and real-time adjustment of the marking content to meet personalized customization needs.

Durability and environmental protection

Laser Coding Machine is not affected by factors such as ambient temperature and humidity, and the marked content will not fade due to friction, chemical corrosion or ultraviolet radiation, ensuring the durability of the logo. In addition, laser marking does not require the use of ink or other chemicals, reducing environmental pollution and health risks, and is in line with the development trend of modern industrial green production.

Wide applicability

The UV flying laser marking machine is suitable for a variety of cable materials, including PVC, PE, rubber and other insulating materials. Laser sources of different wavelengths can be optimized for different materials to ensure clear and lasting marking effects. This wide applicability makes the Laser Coding Printer one of the first choices for identification equipment in the cable industry.

In short, the UV flying laser marking machine has shown great application potential in the cable manufacturing industry with its advantages of high precision, high efficiency, durability and environmental protection. With the continuous advancement of technology and the gradual reduction of costs, this equipment will be more widely used and promoted in the future. For cable manufacturers, choosing a Flying Laser Marking Machine for marking can not only improve product quality and market competitiveness, but also achieve green production and sustainable development.

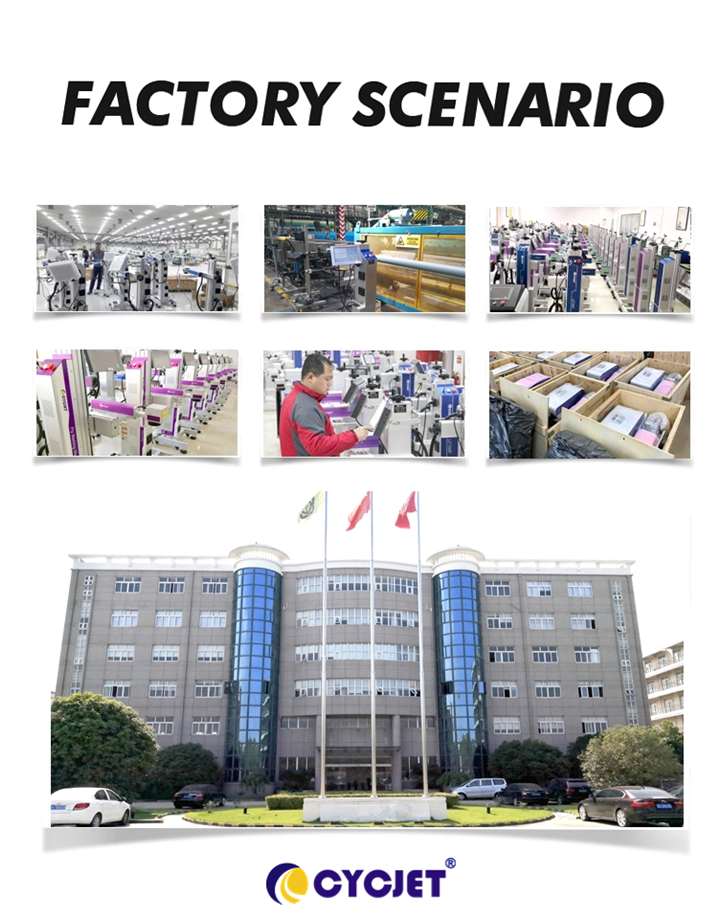

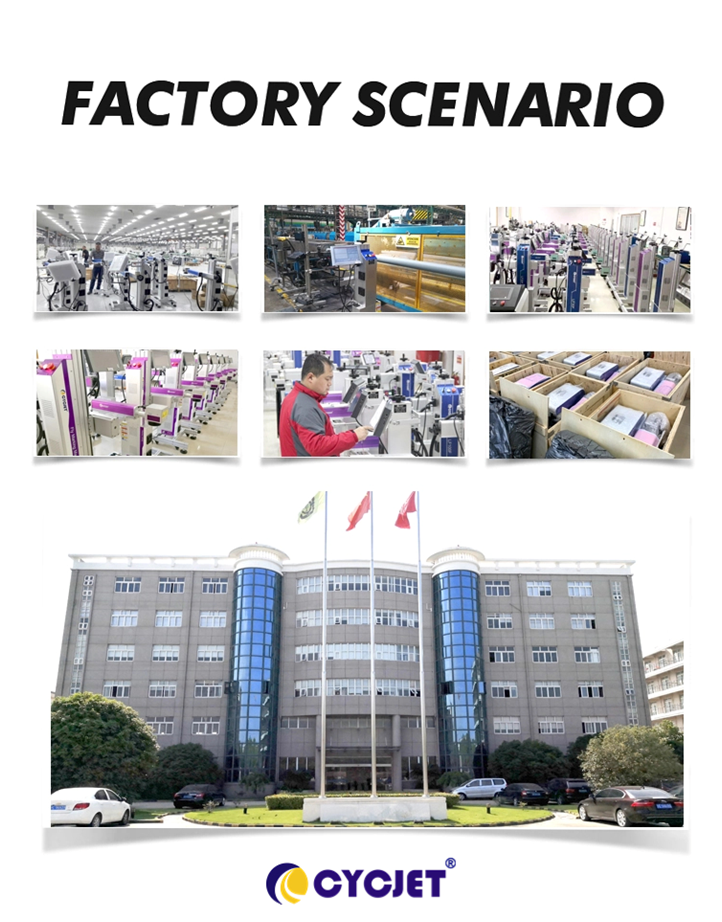

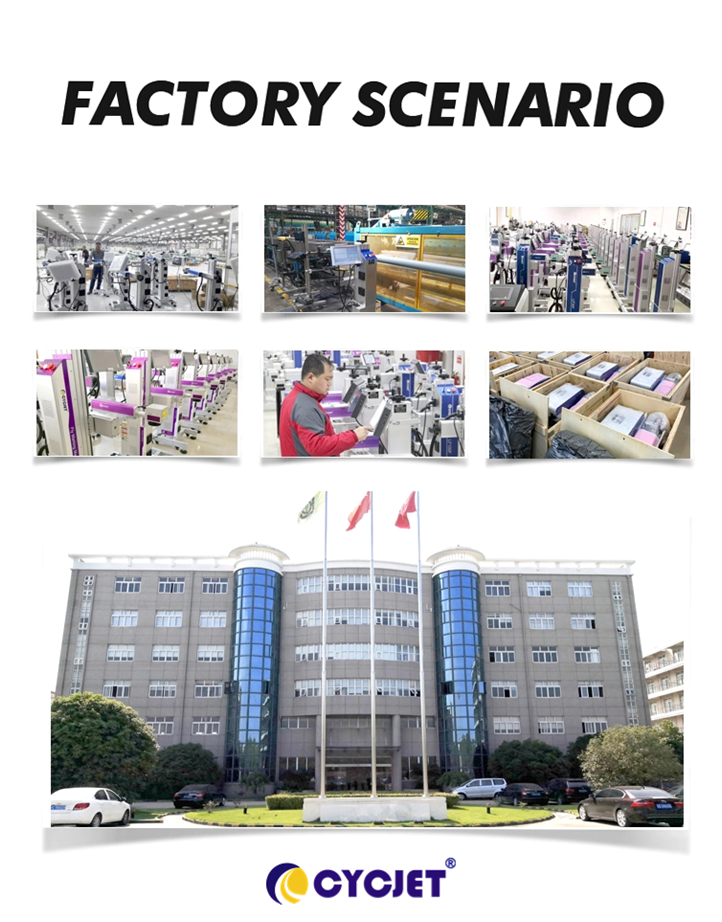

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtu.be/w4YZxOkUT6I

Facebook: https://www.facebook.com/photo/?fbid=797206415759299&set=pb.100064098422560.-2207520000

Linkedin:https://www.linkedin.com/feed/update/urn:li:activity:7158007093390675968

Instagram: https://www.instagram.com/reel/C2t6GsFOBez/?igsh=MzRlODBiNWFlZA==