The echoes of the bells of the Year of the Snake are still lingering, and the breath of the New Year is still in the air. We have embarked on a new journey with hope and dreams in our hearts. Here we wish you all a happy Year of the Snake and a good start to your work!

At the same time, in this early spring season full of hope and vitality, CYCJET Yuchang Industrial Co., Ltd. also ushered in the start of the new year, when everything is revived and full of vitality. On this special day, CYCJET officially pressed the “start button” of the new year, and all colleagues gathered together to start the journey of the new year with full enthusiasm and firmsteps!

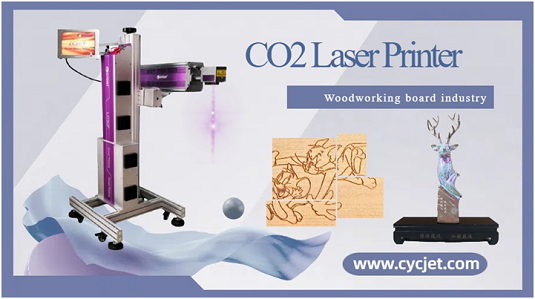

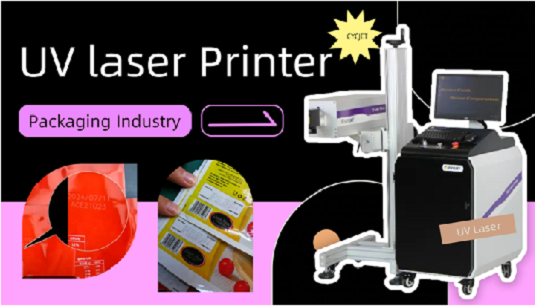

CYCJET deepens the technical research and development of inkjet printers and laser machines, and is committed to launching more efficient, intelligent, and environmentally friendly new equipment to meet the growing needs of customers. For example: High-Resolution Inkjet Printers, CIJ Small Character Inkjet Printers, Automatic Inkjet Printers, Fiber Laser Marking Machines, Handheld Inkjet Printers, etc.

The main application directions are roll film, rulers, batteries, cartons, pipes, beverage bottles, plastic bags, wood, metal, tires, rulers and other materials. According to the needs of different groups, we create a perfect identification solution for each customer, so that the identification is the icing on the cake for the product. CYCJET consolidates its domestic and foreign market position, promotes the globalization of products, and enhances the international influence of the brand.

Since its establishment, CYCJET Yuchang Industrial Co., Ltd. has been committed to providing customers with high-quality inkjet printers and Laser Machine Equipment, and providing personalized product configurations and solutions according to different customer needs. We are well aware that each device carries the trust and expectations of customers, so we always adhere to excellence and continuously improve product quality and service levels.

In the new year, our inkjet printers and laser machines have fully resumed accepting orders. Whether you need efficient and accurate inkjet printers or stable and reliable laser marking machines, CYCJET Yuchang can meet your needs. Our professional team will wholeheartedly provide you with a full range of technical support and after-sales service to ensure that every choice you make will get the most satisfactory return.

At the beginning of the project, we would like to thank all new and old customers for their support and love. It is your trust that gives us the motivation to keep moving forward. In the future, CYCJET will continue to uphold the principle of “easy marking, unlimited printing”, continue to innovate, pursue excellence, and provide customers with better product marking and services.

In the new year, we sincerely wish all our partners a prosperous career, thriving business, rolling in wealth, good health, happy family, and smooth work. Let us work together to create a better future for logos!

CYCJET, set sail with you and head for a more glorious shore!

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/