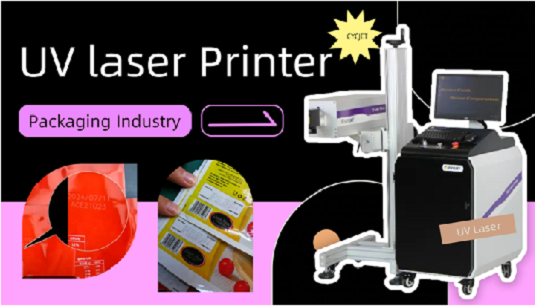

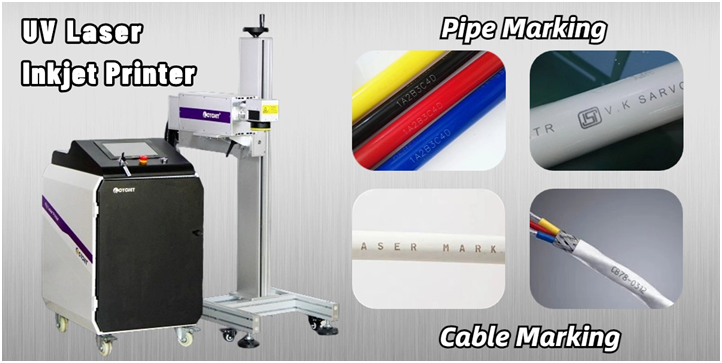

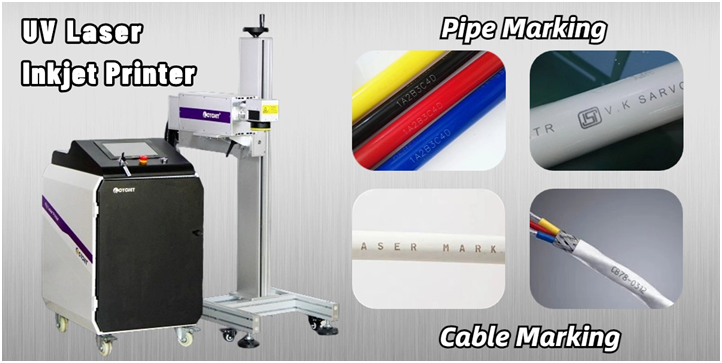

In the rapidly developing electronic products industry, accurate, durable and beautiful marking technology is crucial. With its unique advantages, UV Laser Marking Machines stand out in the field of electronic product marking and become the industry’s preferred technology.

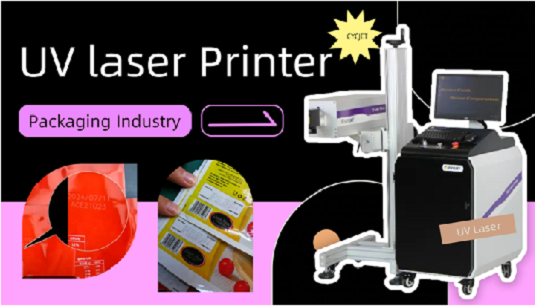

Core advantages of UV laser marking machine

- High precision and micro-processing capabilities

The Laser Marking Equipment uses a short-wavelength UV laser beam to achieve micron-level fine marking. This high-precision processing capability makes it possible to mark small electronic components with clear markings, meeting the strict requirements of electronic products for marking accuracy.

- Non-contact processing

Unlike traditional contact marking methods, UV laser marking is non-contact, which means that there is no physical pressure or wear on electronic components during the marking process. This not only ensures the integrity of the product, but also extends the service life of electronic products.

- Diverse material adaptability

UV laser marking machines can easily handle a variety of materials, including metals, plastics, ceramics, etc., which makes it applicable to a variety of electronic products. Whether it is a mobile phone, computer, smart wearable device or other high-tech products, Laser Coding Machine can provide consistent high-quality identification.

- Environmental protection and efficiency

The UV laser Marking Machine does not produce any chemicals or waste during the working process, and is an environmentally friendly marking technology. At the same time, due to its fast marking speed and low maintenance requirements, the UV laser marking machine performs well in improving production efficiency, which meets the requirements of modern manufacturing industry for environmental protection and sustainable development.

In short, High-Speed laser marking machine plays an increasingly important role in the field of electronic product marking with its advantages of high precision, high efficiency, and green environmental protection. It not only improves the quality and traceability of products, but also reduces production costs and environmental pollution. With the continuous advancement of technology and the continuous expansion of application fields, it is believed that UV laser marking machines will create more possibilities and value in the electronic product manufacturing industry.

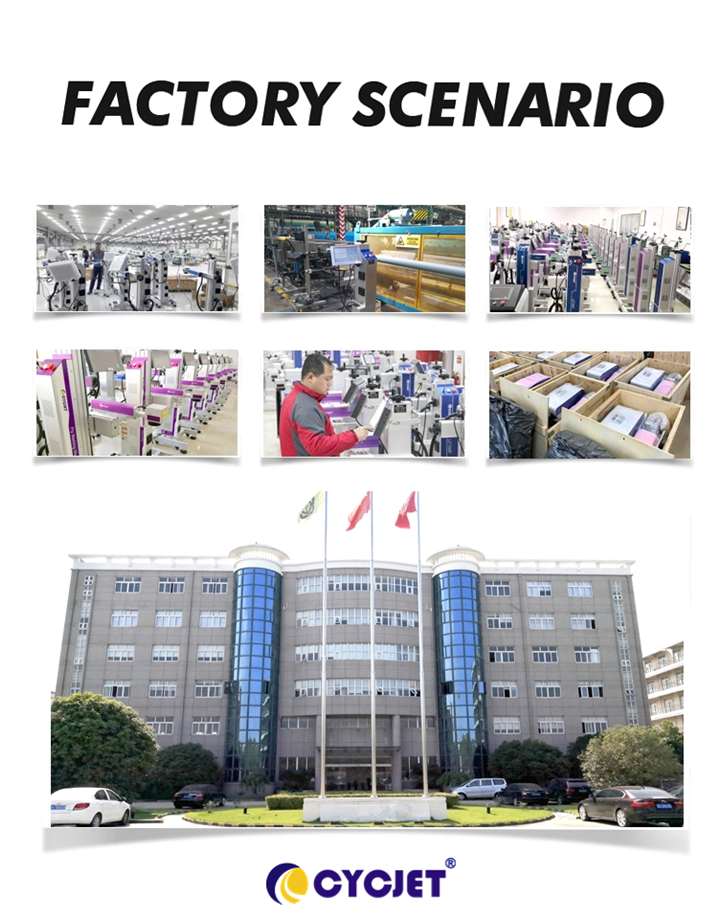

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext. 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtube.com/shorts/tlsf06EyAkI

Facebook: https://www.facebook.com/100064098422560/videos/1662475271279367

Linkedin:https://www.linkedin.com/feed/update/urn:li:activity:7269190750305738752