On the shelves of supermarkets, bottles of mineral water are neatly arranged. They look ordinary, but they contain many elaborate production links. When you pick up a bottle of mineral water and scan the bottle, you can see the clear production date, batch number, manufacturer and other information on it. Behind it may be an “invisible guardian” – the laser marking machine. Today, let us take a deeper look at the mystery of the laser marking machine on the mineral water bottle.

一、 Laser marking makes the logo more durable

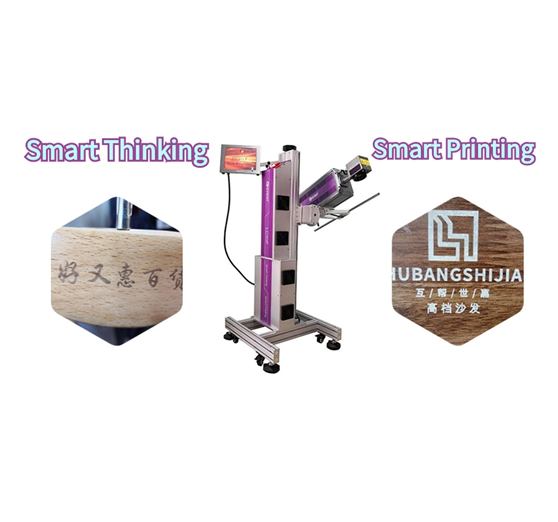

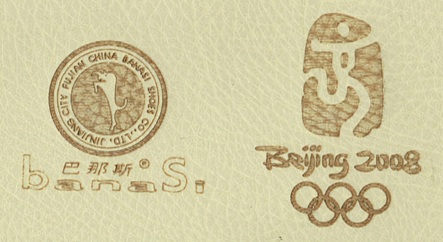

Mineral water bottles are mostly made of PET, which is lightweight and low-cost. Traditional coding methods, such as ink coding, are prone to fading and blurring over time and environmental changes. The laser coding machine uses a high-energy-density laser beam to instantly vaporize the material on the surface of the mineral water bottle, thereby forming a clear and firm logo. Whether the mineral water bottle is exposed to high temperatures or in a humid environment for a long time, the information left by the CO2 Laser Coding Machine is always clear and legible, just like giving each bottle of water an indelible “ID card”.

二、Efficient coding helps speed up production

Mineral water production is usually large-scale and efficient. The laser marking machine has an excellent working speed and can perfectly cooperate with the high-speed production line. On the production line, mineral water bottles flow at a very fast speed. The laser marking machine, with its fast beam movement and precise control, can quickly and accurately complete the coding operation at the moment when each bottle passes. This greatly improves production efficiency, reduces production costs, and brings higher economic benefits to the enterprise.

三、Anti-counterfeiting and traceability, protecting the rights of brands and consumers

For mineral water manufacturers, product anti-counterfeiting and traceability are crucial.High-speed Laser Marking Machines can print complex and detailed QR codes, barcodes and other information on mineral water bottles. These information are highly anti-counterfeit and difficult to copy and tamper with. By scanning these codes, consumers can obtain detailed production information of the products, such as water sources, production processes, test reports, etc., to achieve full traceability of products from production to sales. This not only protects consumers’ right to know but also provides strong support for companies to combat counterfeit and shoddy products and maintain their brand image.

Flying Laser Marking Machines, with their unique advantages, play an indispensable role in the field of mineral water bottle coding. They have made great contributions to the quality assurance, production efficiency improvement, environmental protection and brand protection of mineral water products. With the continuous advancement of science and technology, laser marking technology will continue to innovate and bring more surprises and possibilities to the mineral water industry. Next time when you pick up a bottle of mineral water, take a closer look at the code on the bottle and feel the charm of science and technology behind it.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than 20 years of experience in R&D for different types of handheld inkjet printing solutions, laser printing solutions, portable marking solutions, and high-resolution printing solutions in Shanghai, China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB: +86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtube.com/shorts/uF22JAVVu9A?feature=share

Facebook: https://www.facebook.com/100064098422560/videos/267224125615152

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:6981532693536673792

Tiktok: http://www.tiktok.com/t/ZTRnyUpBM/