In the ever-changing pharmaceutical industry, every technological innovation leads to a leap in product quality. The Laser Marking Machine, a technical equipment that plays an important role in the production of pharmaceutical companies, not only improves the appearance of the product, but also demonstrates excellent performance in terms of safety, efficiency and environmental protection.

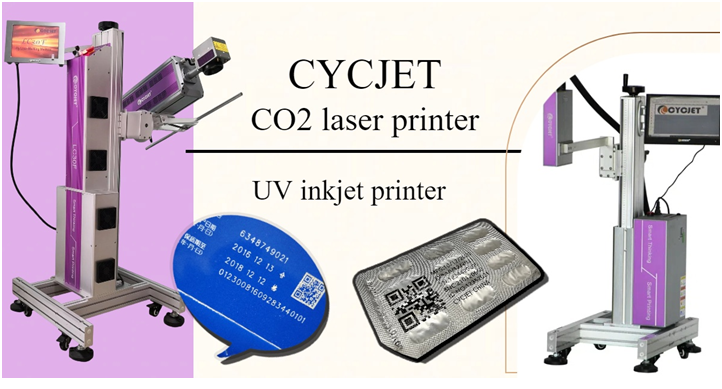

Laser marking machines, with their high precision and high efficiency, shine in the packaging and production process of pharmaceutical products. Whether it is PE, HDPE or ABS material packaging, laser inkjet printers can easily cope with it and achieve fast and accurate inkjet requirements; from production date, batch number to QR code and barcode, laser inkjet printers can accurately present them one by one, so that each product has a unique identity.

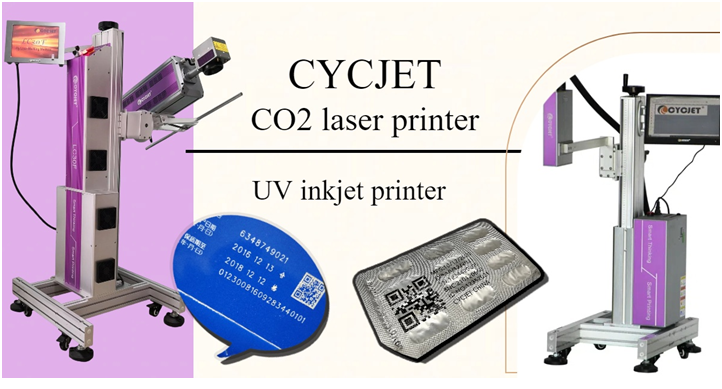

In the production of pharmaceutical products/medical devices, laser inkjet printers have shown their unique advantages. By matching different types of lasers, laser coding equipment can adapt to the marking needs of different materials. For example, CO2 Laser Coding Equipment is faster in processing flexible non-metallic materials. UV Laser Marking Machines often used for batch coding operations of protective masks and other materials, but it also has significant advantages in the processing of metal materials. Widely used in coding engraving of metal medical devices.

Compared with traditional inkjet coding technologies, such as mechanical engraving, chemical etching and inkjet printing, laser inkjet technology has significant non-contact advantages. This feature fundamentally ensures hygienic conditions for production and avoids material residue contamination that may occur in traditional processing methods. Today, when medicines are in close contact with people’s lives, this pollution-free processing method is particularly important.

The advantage of beautiful and long-lasting marking effect is that the laser content is not easy to fade and blur, and it can remain clear even after long-term use and friction. This high-quality mark not only improves the beauty of the product, but also enhances consumers’ trust and satisfaction with the brand.

With the continuous development of automation technology, laser coding equipment has also achieved a high degree of automation integration. These equipment’s can be seamlessly connected with the production line, including but not limited to a series of packaging machinery such as Multi-Column Packaging Machines, labeling machines, carton paging conveyors, etc., to achieve a fully automated production process. The improvement of efficiency and reduction of costs have brought significant economic benefits to the pharmaceutical industry.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext. 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video:https://youtu.be/sRp_kJOp3IE

Facebook:https://www.facebook.com/100064098422560/videos/826499158535395

Tiktok:https://www.tiktok.com/t/ZTRnoREYu/

Linkedin:https://www.linkedin.com/feed/update/urn:li:activity:6986529551359098880