In today’s highly competitive manufacturing industry, laser marking machines, with their efficient production and clear marking characteristics, have become a powerful tool for various industries to improve production efficiency and product identification. The following are important aspects of discussing the application of laser marking machines in production:

1. Innovative production technology

The laser marking machine uses high-energy laser beams to engrave the material surface, making the marking process more efficient and precise, thus improving the innovation of the overall production process.

2. High-speed marking

The Fiber Laser Marking Machine can complete the marking process in a very short time and has a higher production speed than traditional marking methods. This makes the rhythm of the production line more compact and the production capacity significantly improved.

3. Clear and detailed markings

The laser marking machine can achieve clear marking of various materials by adjusting the laser parameters. Whether it is text, pattern, or QR code, it can show extremely high detail and clarity.

4. Contactless marking

Since the laser marking machine is a non-contact marking method, it can avoid direct contact with the workpiece, reduce damage and deformation of the material surface, and ensure the appearance and quality of the product.

5. Multi-material applicability

Laser Coding Machines have good adaptability to a variety of materials during the marking process, including metals, plastics, ceramics, etc., making them widely used in production in different industries.

6. Highly personalized

Laser marking technology provides highly personalized marking options for products, thereby meeting the market’s growing demand for personalized customization and enhancing product competitiveness.

7. Quality traceability and traceability

Products marked by laser marking machines can realize quality traceability and traceability of the production process, which helps to improve the quality management level of products.

8. Energy saving and environmental protection

Compared with some traditional marking methods, Stationary Laser Marking Machines can use energy more effectively and reduce waste generation, thereby achieving energy conservation and environmental protection in production to a certain extent.

9. Widely used in industries

Laser marking machines are widely used in electronics, automobiles, medical equipment, aerospace, and other industries, providing efficient and accurate marking solutions for production in different industries.

Therefore, the production application of portable desktop laser marking machines not only improves production efficiency but also injects more innovative elements into product identification, becoming an indispensable and important tool in modern manufacturing.

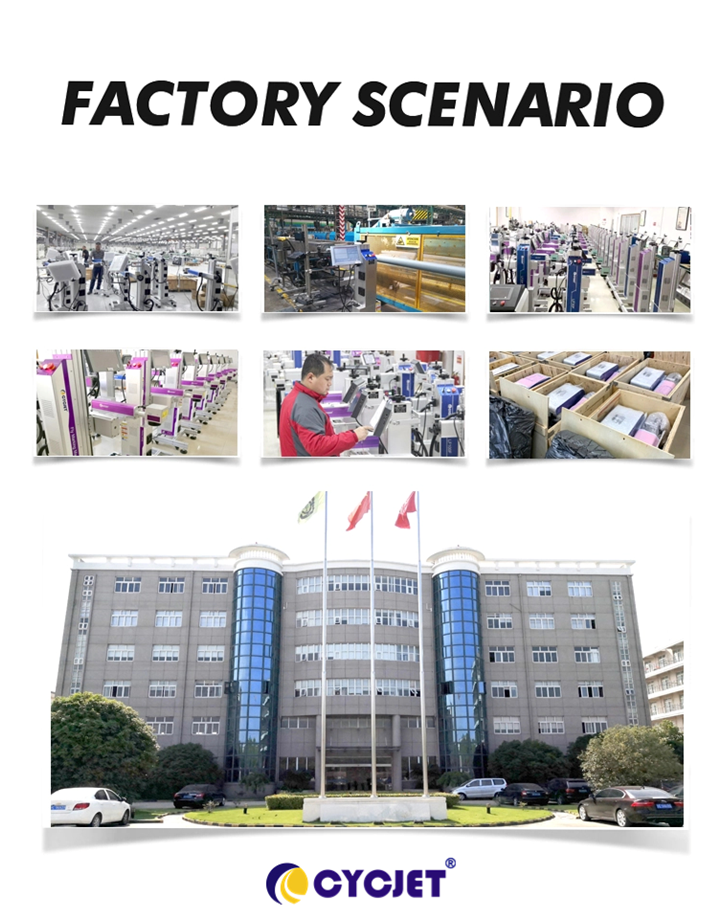

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than 19 years of experience in R& D in different types of handheld inkjet printing solutions, Laser printing solutions, portable marking solutions, and High-Resolution Printing solutions in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/