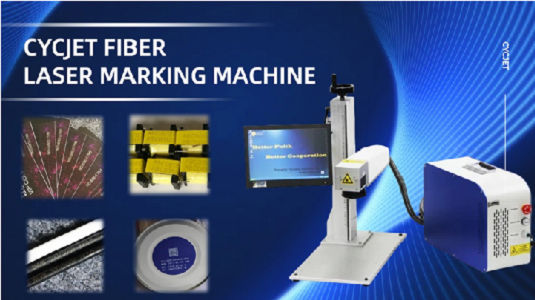

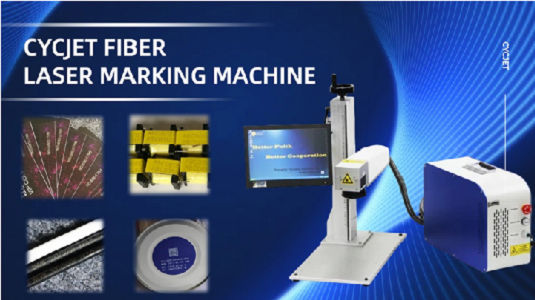

As a metal parts manufacturer, have you ever encountered these problems? Traditional marking methods (such as ink printing and mechanical engraving) are easy to wear and tear, and customers complain that the markings are unclear? Manual operation is inefficient and there is no time to rush large orders? Want to improve the quality of your products, but ordinary marking methods seem cheap? If the answer is “YES”, then you need to know about the desktop laser marking machine, which is becoming an efficiency revolution in the metal processing industry!

Why is laser marking more cost-effective than traditional methods?

1.0 consumables, long-term cost saving

Traditional inkjet printing requires continuous purchase of ink and solvents, and the knives for mechanical engraving will also wear out. However, laser marking machines do not require any consumables and can work as long as they are powered on, which can save a lot of costs in the long term.

2.3 times the speed, 24-hour non-stop

Manual marking or mechanical engraving is inefficient, while laser marking can complete a LOGO or serial number in 1 second, supports automated assembly line docking, and can easily handle large-volume orders.

3.Permanent marking, no fear of wear and tear

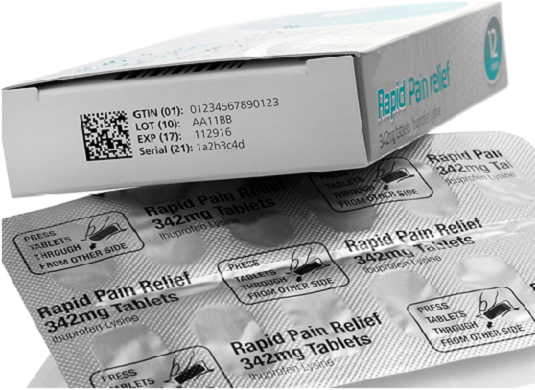

Fiber laser marking machine directly forms an oxide layer or micro-groove on the metal surface, which will not fade due to friction, high temperature, acid and alkali environment, ensuring that the product can be traced for life.

Why is the desktop laser marking machine more suitable for metal accessories?

1.High precision, even tiny fonts can be clearly engraved

Whether it is stainless steel, aluminum alloy, copper, or titanium alloy, laser marking can achieve ultra-high precision of 0.01mm, even tiny QR codes and precision part numbers can be clearly read.

2. Non-contact processing, no damage to the workpiece

Traditional mechanical engraving may cause metal deformation or burrs, while laser marking has no physical contact and will not affect the precision and strength of metal accessories. It is especially suitable for high-precision parts.

3.Flexible customization, one-click switching of different patterns

Just import the design file on the computer, you can quickly switch LOGO, text, serial number, QR code and other content without changing the mold, which is especially suitable for small batch and multi-variety production.

How to choose a reliable stationary laser marking machine?

There are many laser devices on the market, but when purchasing, you should focus on:

1. Laser power: 20W-50W fiber laser is recommended for metal marking to ensure depth and speed.

2.Software compatibility: Supports design software such as AutoCAD and CorelDRAW, which is convenient for direct import of drawings.

3.Stability: High-quality lasers have a lifespan of up to 100,000 hours, reducing maintenance troubles.

4. After-sales service: Brands that provide installation training and technical support are more trustworthy.

Customer real case: efficiency increased by 300%, defect rate reduced to 0%

A precision hardware factory used to use mechanical engraving, marking up to 2,000 workpieces per day, and 10% were scrapped due to burr problems. After changing to a laser marking machine: the speed increased to 6,000 pieces/day, easily handling peak season orders; the defect rate dropped to 0, and customer complaints decreased by 90%; the return on investment was 3 months, saving consumables and labor costs in the long term.

In short, in the fiercely competitive metal processing industry, efficiency, quality, and brand image determine profits. Portable desktop laser marking machines can not only help you reduce costs and increase efficiency, but also make product logos more refined and improve the overall grade.

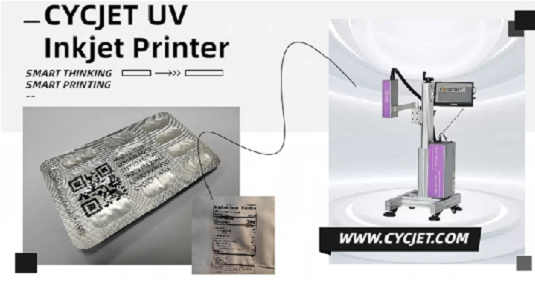

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High