Clear, durable marking is crucial in the production and distribution of PVC pipes. Whether it’s product model numbers, production batches, brand logos, or industry certification marks, efficient and precise marking methods are essential. Traditional inkjet printing or labeling methods are susceptible to wear and fading. Fiber laser marking machines, with their high precision, high speed, and permanent marking, are the ideal choice for PVC pipe marking.

一、Why choose a fiber laser marking machine for PVC pipe marking?

- Permanent marking, abrasion-resistant, and corrosion-resistant.

PVC pipes are commonly used in industries such as construction, water conservancy, and power generation. They are exposed to outdoor and humid environments for extended periods, and markings printed with ordinary inks can easily blur and fade. Fiber laser marking machines, however, use high-energy laser beams to create a permanent mark on the PVC surface. This mark resists fading due to friction, chemical corrosion, or UV exposure, ensuring product information remains legible for extended periods.

2. High-precision marking, suitable for complex patterns and tiny text.

Fiber laser printers utilize a high-precision galvanometer system, enabling micron-level precision marking on PVC pipes. Whether barcodes, QR codes, serial numbers, or company logos, these markings are precisely rendered. This is particularly important for industries requiring product traceability (such as building materials, medical, and chemical industries), ensuring that every piece of pipe can be efficiently identified and managed.

- Non-contact processing, no damage to the PVC material.

Unlike traditional mechanical engraving, laser marking is a non-contact process, which does not impose physical pressure on the surface of PVC pipes, preventing deformation or cracking. Furthermore, laser energy can be precisely controlled to ensure an appropriate marking depth without affecting the pipe’s structural strength and durability.

- Environmentally friendly and energy-saving, complying with international production standards.

Fiber laser coding machines eliminate the need for consumables such as inks and solvents, reducing waste pollution and complying with environmental regulations such as EU RoHS and REACH. Furthermore, laser marking machines offer low power consumption, significantly reducing production costs over time and enhancing a company’s environmental image.

二、 Innovative Applications: Intelligent Traceability and Brand Anti-Counterfeiting

① Dynamic QR Code Traceability System

A unique QR code is laser-marked on each piece of PVC pipe. Customers scan the code to access information such as the production date, quality inspection report, and installation instructions, enhancing supply chain transparency. For export-oriented companies, this technology meets the stringent traceability requirements of the European and American markets.

② Anti-Counterfeiting Marking

By adjusting laser parameters, microscopic markings can be applied to the surface of PVC. This technology effectively prevents counterfeiting and protects brand equity, making it particularly suitable for the high-end building materials market.

③ Automated Line Integration

Fiber laser marking machines can be easily integrated into automated production lines. Combined with robotic arms or conveyor belts, they enable high-speed in-line marking of PVC pipes, improving production efficiency and reducing manual intervention, making them suitable for large-volume export orders.

三、How to choose a high-speed laser marking machine suitable for PVC pipes?

- Power Selection: A 20W-50W fiber laser is sufficient for PVC marking. Excessive power may cause carbonization of the material.

- Marking Format: Select an appropriate worktable or rotary fixture based on the pipe size to ensure precise marking placement.

- Software Compatibility: Supports design software such as AutoCAD and CorelDRAW, and can be integrated with enterprise ERP/MES systems for automated data transmission.

Enhance Brand Value, Start with Professional Marking

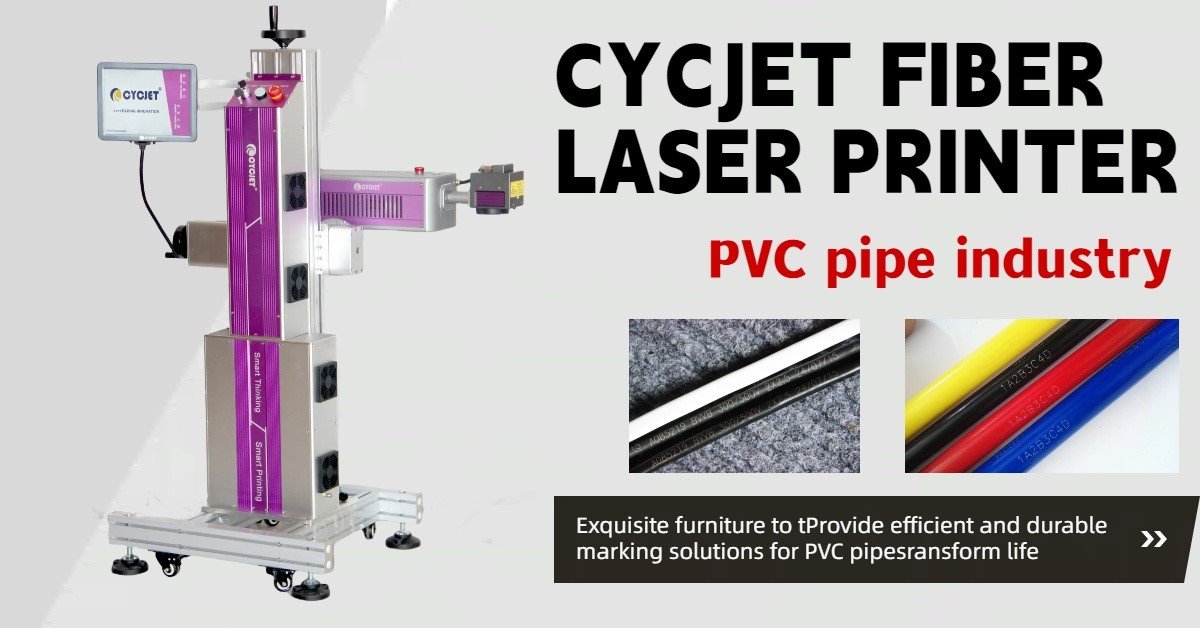

In the fiercely competitive international trade market, high-quality marking not only elevates product quality but also strengthens customer trust. The CYCJET fiber laser marking machine, with its efficient, precise, and environmentally friendly features, is the optimal solution for PVC pipe marking. Whether boosting production efficiency or meeting international market compliance requirements, investing in a fiber laser marking machine will bring long-term returns to your business.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/