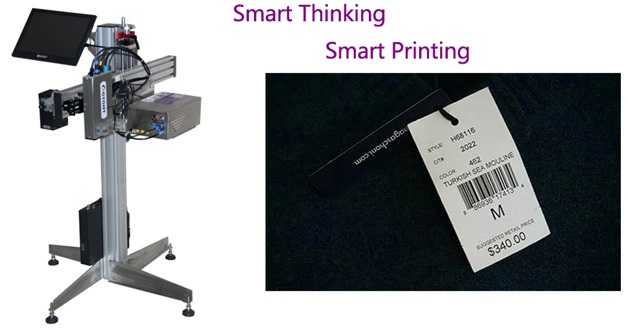

Clothing tag is a brand hanging on clothing, including some clothing materials, washing precautions and other information, its materials include coated paper, special paper, PVC, canvas, ribbon, metal, bamboo, leather, PU, silicon. Although the hangtags of each garment enterprise have their own characteristics, most of them are printed with the factory name, factory address, telephone number, zip code, logo, barcode, etc. on the hangtag. Today, I will share with you the principle of using the tag UV inkjet printer.

With the popularity of traceability anti-counterfeiting barcodes, more and more garment enterprises provide anti-counterfeiting traceability to products by printing barcodes on hang tags. The clothing anti-counterfeiting tag is based on modern information anti-counterfeiting technology. A piece of clothing corresponds to a random unique anti-counterfeiting code. The enterprise enters this anti-counterfeiting code into the query system in advance, and consumers verify the authenticity by checking the anti-counterfeiting code after purchasing the product.

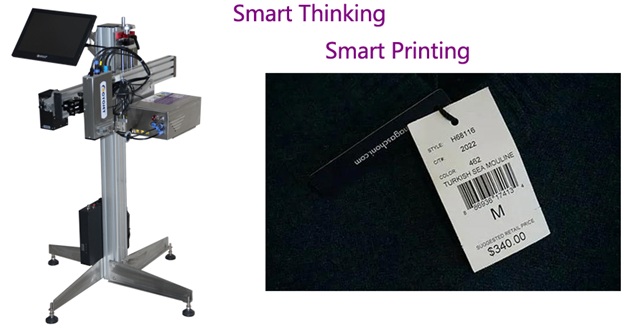

The tag UV inkjet printing machine is an inkjet printer that prints variable data barcodes or other information for clothing tags. It can print variable data on various materials. The anti-counterfeiting and traceable UV inkjet printer adopt imported industrial piezoelectric print heads, industrial Android system, and intelligent electronically controlled negative pressure ink supply system. It has the functions of non-stop ink change and one-key maintenance. The printing effect is outstanding, and it is suitable for a wide range of materials. It has the characteristics of high printing accuracy, fast speed, easy maintenance, quick-drying ink, no blockage of the nozzle, good adhesion and no damage to the surface of the printed items.

The clothing enterprise generates different unique anti-counterfeiting codes through its own anti-counterfeiting system, and assigns a code to each clothing tag through the UV inkjet printer. The relevant information of the clothing recorded in this exclusive anti-counterfeiting code includes the information of the clothing manufacturer, the brand of the clothing, clothing production batch number, clothing production scene, etc.

In addition, there is also the specific process of clothing production, starting from clothing design, all raw materials of clothing, sewing production process, packaging and transportation process, specific channel distribution, store retail, etc., until the final consumer purchase, all traceability information can be recorded in the anti-counterfeiting code.

Consumers can check all information about clothing by scanning the code when purchasing clothing, and know whether the clothing is the selected brand product; clothing enterprises can comprehensively control clothing anti-counterfeiting traceability data through their own database system, obtain market dynamics, ensure clothing quality, avoid smuggling behavior and provide basic guarantee for the healthy development of the brands.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 16 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com