As a high-precision and high-efficiency marking method, laser marking technology is widely used in the metal products industry. With the development of the metal products industry, the demand for product identification is also increasing. Fiber laser marking machines can not only mark metal products, but can also be used in quality monitoring and anti-counterfeiting, and have become an indispensable tool in the metal products industry.

Laser marking machines have the advantages of high precision and high efficiency. The laser beam can realize non-contact marking on the metal surface without causing wear or deformation of the metal surface, ensuring the clarity and durability of the marking. At the same time, laser marking technology is simple to operate, fast in marking, suitable for mass production, and improves production efficiency.

Secondly, the laser marking machine is simple to operate, highly efficient, and can achieve mass production, effectively reducing energy consumption and carbon emissions. Traditional marking methods often require large amounts of energy supply and long processing times, while laser marking technology directly marks the metal surface through laser beams, saving energy consumption and improving production efficiency.

At the same time, laser coding machines are flexible and adaptable. By adjusting the parameters of the laser beam, marking of different metal materials can be achieved, including iron, copper, aluminum, etc. In addition, laser marking technology can also achieve depth control of metal surfaces to meet different application needs.

However, laser marking technology still faces some challenges in the metal products industry. The first is the high cost of equipment. Especially for small businesses, purchasing and maintaining laser marking equipment requires a large investment. Secondly, laser marking equipment has certain difficulties in processing irregular-shaped metal products and needs further improvement and optimization.

However, with the continuous advancement of science and technology, the application prospects of laser marking technology in the metal products industry are very broad. In the future, it is foreseeable that laser marking technology will continue to innovate and improve, such as increasing the marking speed and expanding the scope of application, to further meet the needs of the metal products industry and make greater contributions to environmental protection.

In summary, laser coding printer has significant environmental friendliness in the metal products industry. Through the characteristics of no pollution, no noise and high efficiency, laser marking technology can not only meet the marking needs of metal products, but also reduce the negative impact on the environment. It is believed that in the future development, laser marking technology will be more widely used and promoted

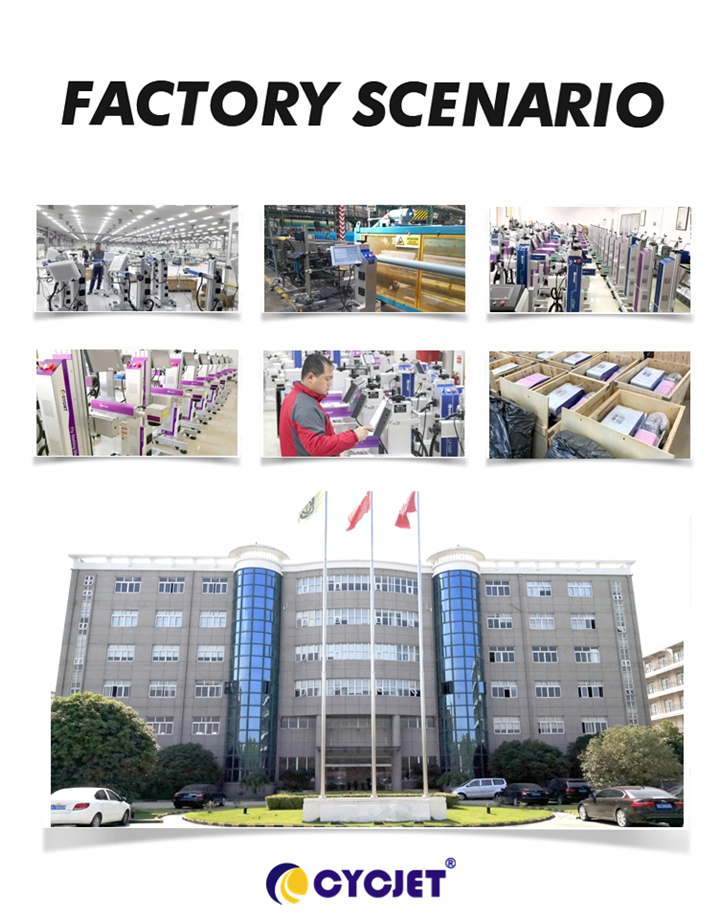

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/