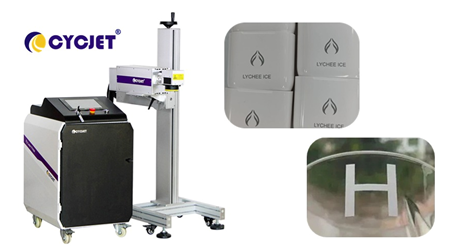

Compared with other laser marking methods, UV Laser Marking Machine belongs to cold processing technology, which reduces the restrictions on imaging precision and thermal impact to the minimum. Moreover, it can be used in a wide range of fields, is more economical, environmentally friendly, and low-carbon, and is a major leap forward in laser processing technology, playing a constructive and significant role in quality traceability, anti-counterfeiting and other fields.

The Principle of UV Laser Marking Machine

UV Laser Printer, also known as cold light source marking, uses laser beams to mark permanent marks on the surface of various materials. The UV laser marking method is different from the long-wave laser, which produces evaporation of surface materials to expose deep materials. Instead, it uses short-wavelength lasers to directly break the molecular chains of materials, thereby revealing the desired etched patterns, texts, etc. In addition to copper materials, UV laser machines are suitable for various metal and non-metal materials, and can process a wider range of materials.

UV laser marking machines are widely used in various industries such as 3C electronics, food packaging, hand jewelry, craft gifts, cosmetics, integrated circuits, electrical components, textiles and clothing, medical equipment, etc. They can perform rapid marking, coding, engraving, scribing, micro-hole and other processing.

Technical Advantages of UV Laser Marking Machine

Unlike infrared processing, the UV laser focus spot is extremely small, and the processing heat-affected zone is small, which can achieve ultra-fine marking and special material marking. It is the first choice for customers who have higher requirements for marking effects. The technical advantages of UV Laser Coding Machines are mainly:

1. Non-destructive Marking

The UV laser marking machine uses a 355nm wavelength cold light source, with a small heat-affected area and non-contact non-destructive marking, which will not cause deformation, damage or burning of the work piece and has a high yield rate.

2. Ultra-fine, Good Effect

The High-Speed Laser Marking Machine has good beam quality, extremely small focused spot, up to nanometer level, clear processing pattern, fine texture, and high-end feeling.

3. Wide Range of Applicable Materials

Suitable for common types of metal and non-metal materials, such as wood, paper, rubber, plastic, glass, leather, jade, monocrystalline silicon wafers, thin ceramics, IC grains, alumina, LCD screens, metals, and special Materials, etc., especially in the field of brittle and fragile work pieces, the processing advantages are more significant.

With the increasing maturity of laser processing technology and the continuous expansion of its application fields, Flying Laser Marking Machine processing has become an irreplaceable and rigid demand in the fields of 3C electronics, automobile manufacturing, smart home, home appliances, and drug traceability.

The market demand for UV laser equipment with reliable quality, powerful functions, and easy-to-use intelligence is growing day by day. CYCJET can provide customized technical solutions and professional services according to the actual needs of customers, helping customers improve their core competitiveness.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://youtu.be/keNsWc_lauo

Facebook: https://www.facebook.com/100064098422560/videos/644076704472578

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:7131097748744912896