In today’s highly competitive market environment, product identity and brand image are crucial to consumers. As part of the packaging industry, bottle caps, as the “first impression” of a product, bear the important task of conveying information and attracting consumers. As an advanced inkjet printing technology, the application of UV inkjet printers on bottle caps has brought significant advantages to manufacturers and consumers.

Advantages of UV inkjet printers in bottle cap applications:

1. Clarity and stability:

Inkjet printing machine can ensure the clarity and stability of QR codes or other markings. Whether it is production date, batch number or other key information, it can be presented clearly and permanently. This stability is very important for consumers to be able to quickly read and obtain relevant information when purchasing products.

2. Drying time and ink adhesion

The special UV ink of the Industrial Inkjet Printer has instant drying characteristics, which means that once the printing is completed, the ink will dry immediately and no wet marks will remain on the bottle cap. This is very important for the production process, as wet markings can affect the appearance and hygiene of the cap. In addition, the ink’s reliable adhesion ensures that the marks will not wear off or fade easily.

3. Versatility:

UV inkjet printers can not only print high-resolution graphics and text, but can also implement various encoding methods such as bar codes and QR codes to meet the needs of different fields. This versatility makes the application of UV inkjet printers on bottle caps highly flexible.

4. Environmental protection:

Online Inkjet Printer uses ultraviolet light curing technology, which does not require the use of solvent inks and meets environmental protection requirements. This helps reduce negative impacts on the environment while meeting growing environmental demands.

5. Wide range of applications:

UV inkjet printers are widely used in card making, labelling, printing and flexible packaging, hardware accessories, beverages and dairy products, pharmaceutical and health care products industry, bottle cap industry and many other fields. This shows that the application of UV inkjet printers on bottle caps has broad market prospects and demand.

Chiller configuration of UV inkjet printer

During operation, the UV inkjet printer will generate high temperature due to long-term operation. If the temperature is too high, it will affect the normal operation of the equipment and even cause equipment failure. Therefore, a chiller is needed to cool down the Large Character Inkjet Printer and maintain its normal operating temperature.

In the bottle cap industry, UV inkjet printers stand out for their high definition, stability, versatility and environmentally friendly features. In order to ensure its normal and stable operation, it needs to be equipped with a laser chiller. The chiller needs to meet the following requirements: sufficient cooling capacity to prevent equipment from overheating, appropriate head and flow to meet the cooling needs of different equipment, and a high-precision temperature control system to maintain stable water temperature.

With the continuous advancement of technology and the expansion of application scope, the application of high-speed inkjet printers in the bottle cap industry will continue to exert its advantages and bring more innovation and value to the packaging industry.

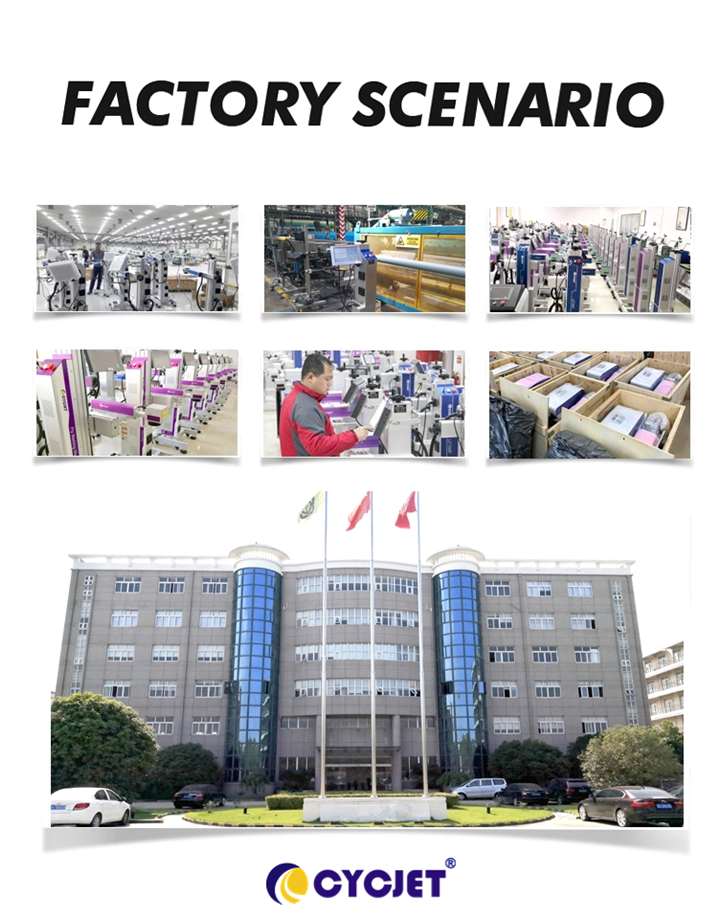

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video:https://www.youtube.com/shorts/A_ESdHUsmmI

Facebook: https://www.facebook.com/100064098422560/videos/628215599390909

LinkedIn: https://www.linkedin.com/feed/update/urn:li:activity:7127167978529329152