In the packaging industry, marking and coding is an essential part. In the past marking methods, and the printing of packaging cartons mainly relied on traditional printing technologies, such as screen printing or offset printing. However, these traditional methods have some obvious shortcomings, such as unstable printing quality, single color, and poor durability.

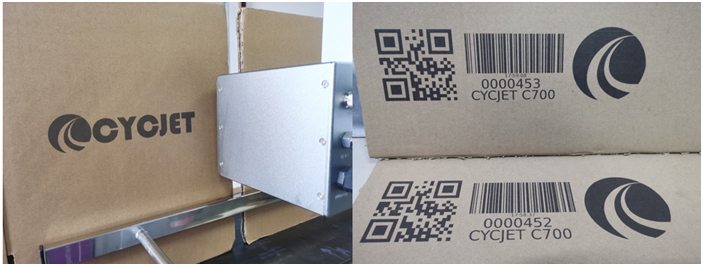

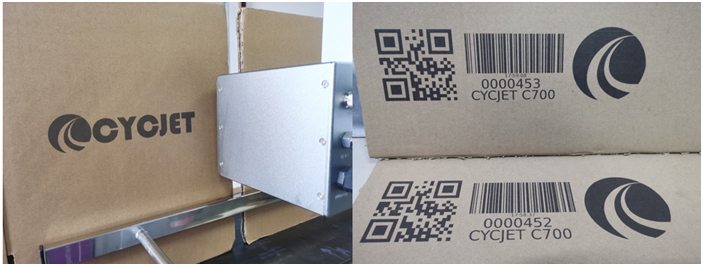

With the advancement of science and technology, and the emergence of a new marking method, the UV Inkjet Printer has brought revolutionary changes to the packaging industry.

Disadvantages of traditional logos

1. Unstable printing quality: Traditional printing technology is subject to many factors, such as ink, paper, etc., which may lead to unstable printing quality and large color deviations.

2. Single color: Traditional printing methods usually only provide limited color choices and cannot meet the personalized needs of some special products.

3. Poor durability: Traditionally printed cartons are prone to fading and falling off during long-term transportation and storage, affecting the brand image.

Advantages of UV inkjet printer

1. High-quality printing: Inkjet Printers use high-precision nozzles, which can provide high-quality printing results with bright and long-lasting colors.

2. Diversified designs: UV inkjet printers can support a variety of designs, including text, patterns, pictures, etc., to meet the personalized needs of different products.

3. Efficient and convenient: UV inkjet printers are simple to operate and can achieve fast and efficient logo printing, greatly improving production efficiency.

4. Environmental protection and safety: The spraying process of the Online Inkjet Printer is pollution-free and meets environmental protection requirements. At the same time, the equipment is safe and reliable, reducing production risks.

Application direction of UV inkjet printer

1. Implement personalized identification on product packaging: Use a UV inkjet printer to provide a unique identification for each packaging box to improve product recognition.

2. Real-time tracking of product information: By printing production date, serial number, and other information on cartons, real-time tracking of products can be achieved and the efficiency of supply chain management can be improved.

3. Enhance brand image: High-quality, long-lasting logos can enhance brand image and enhance consumers’ trust in the brand.

4. Adapt to various packaging materials: large large-character inkjet printer is suitable for various packaging materials, such as paper, plastic, glass, etc., and adapts to different production environments.

To sum up, traditional printing methods can no longer meet the needs of the modern packaging industry, and UV inkjet printers have gradually become mainstream with their high-quality, diverse, efficient, and convenient marking methods. By printing labels on cartons, companies can not only improve product recognition and achieve real-time tracking but also enhance brand image and adapt to various packaging materials. Therefore, high-resolution inkjet printers have broad application prospects in the packaging industry.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET has more than 19 years of experience in R& D in different types of handheld inkjet printing solutions, Laser printing solutions, portable marking solutions, and High-Resolution Printing solutions in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/