In the field of food packaging, packaging materials vary, including plastic, paper, glass, metal, etc. Different materials have different requirements for inkjet coding. With its excellent performance and professional technology, CYCJET small character inkjet printer can adapt to various common food packaging materials and provide food companies with efficient and reliable inkjet coding solutions.

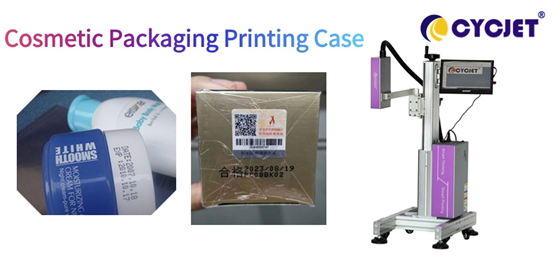

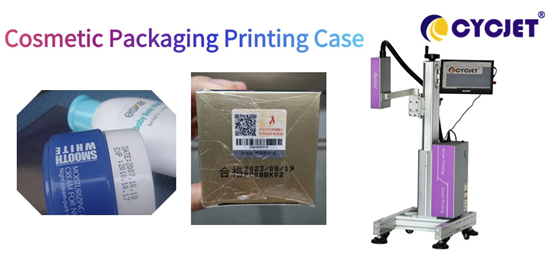

Plastic is one of the most common materials in food packaging and is widely used in beverage bottles, food cling film, plastic bags, etc. The ink equipped with CYCJET small character inkjet printer adopts a special formula that can firmly adhere to the plastic surface. Even after long-term transportation and storage, it is still clearly identifiable, ensuring that consumers can accurately obtain product information.

In addition to plastic packaging, paper packaging is also widely used. Especially in some high-end food or gift packaging, the use of dark paper is very common. CYCJET CIJ inkjet printer can print text and patterns with high contrast, ensuring that the information is clearly visible on a dark background. For example, on a dark gift box packaging, CYCJET inkjet printer can print white information such as production date and shelf life, with high contrast and clear fonts, allowing consumers to easily identify product information when purchasing.

Glass bottles are often used to package high-end beverages, sauces, jams and other foods. These products often need to be sterilized or baked during the production process. The ink of the CYCJET small character inkjet printer has excellent high temperature resistance, which can ensure that the code remains stable in a high temperature environment. For example, in jam products in glass bottles, the code information printed by the CYCJET inkjet printer can withstand the high temperature sterilization process and will not fade or fall off even at high temperatures, ensuring that the code information is clear and readable throughout the product’s life cycle, providing strong protection for food safety and quality traceability.

Whether on complex packaging materials or in harsh environments such as high temperature and humidity, CYCJET online inkjet printers can ensure clear, firm and durable inkjet coding, making your food packaging coding more professional and reliable and safeguarding food safety and corporate image!

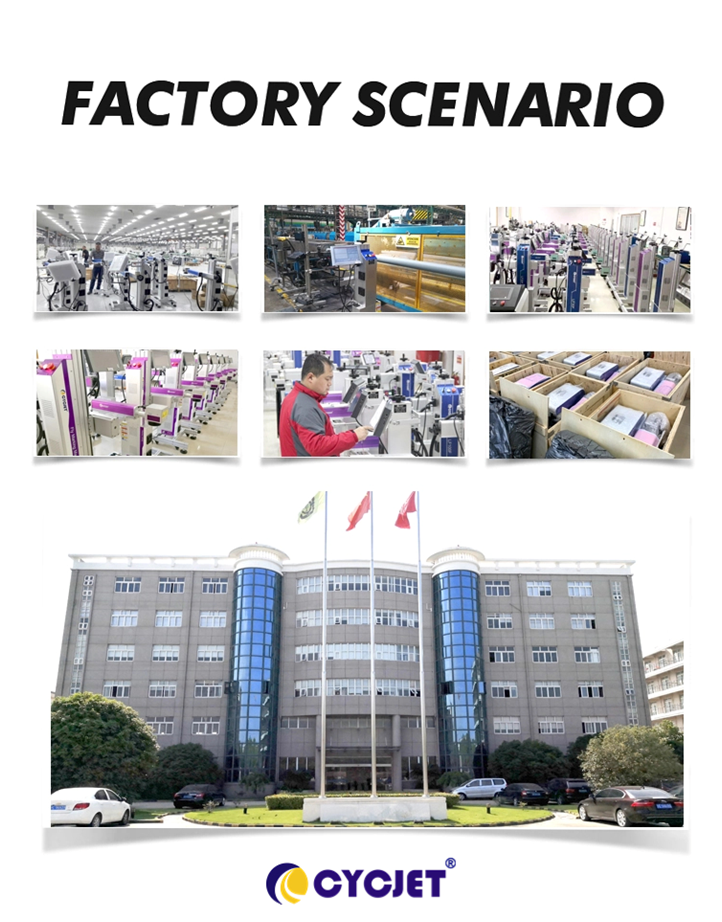

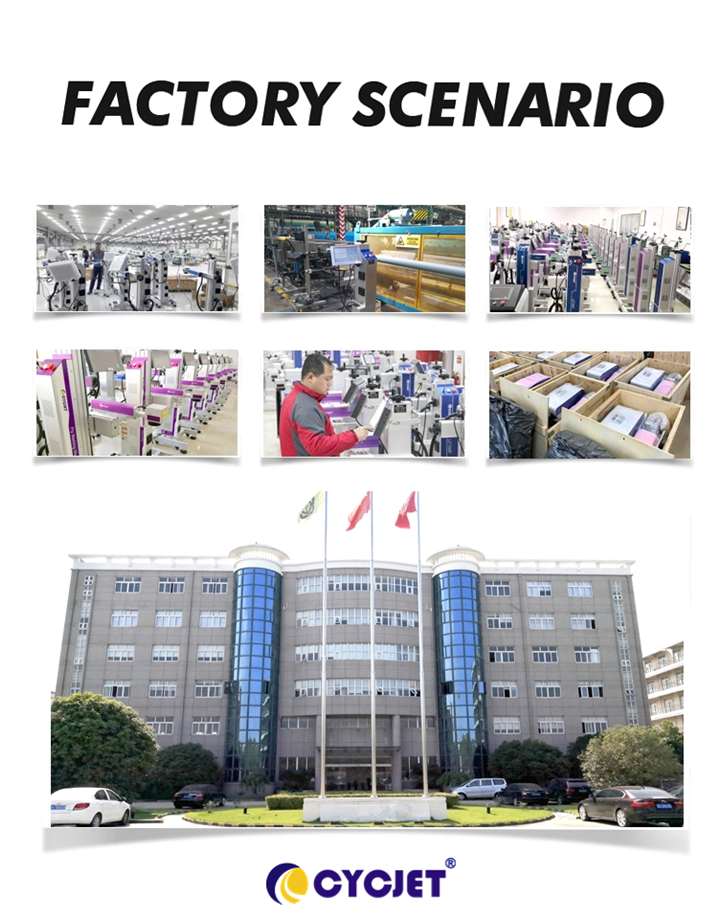

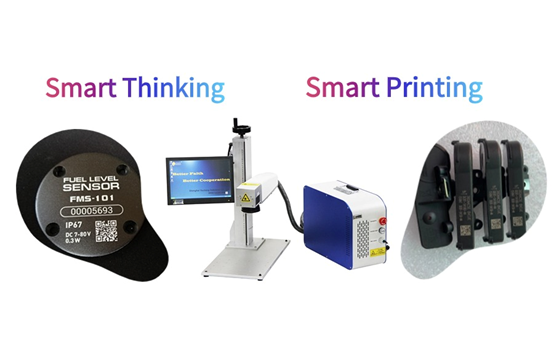

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 19 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB: +86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://www.youtube.com/shorts/u6yVBbw86OU

Facebook: https://www.facebook.com/100064098422560/videos/766386465433516

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:7165541677128990721