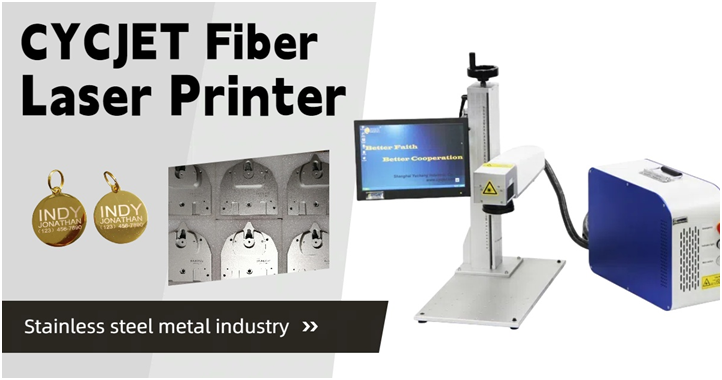

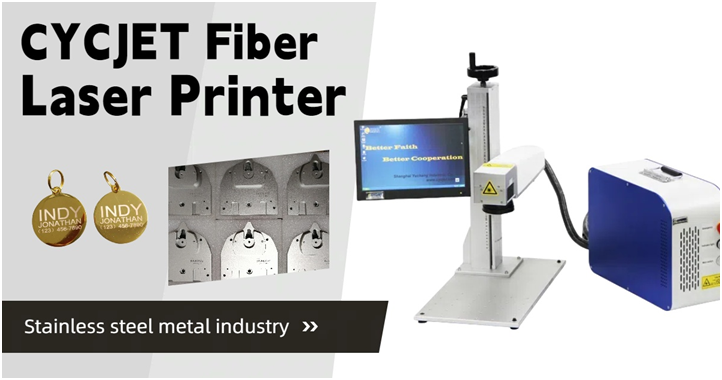

Stainless steel laser marking machine is a device that uses laser technology to mark stainless steel and other metal materials. The laser marking machine uses a laser beam to process stainless steel materials. After the laser beam is focused, it can generate high temperature and high pressure on the surface of the material, thereby achieving the effect of engraving. The laser beam of the Fiber Laser Marking Machine has a high energy density and can evaporate the surface of the material in a very short time, thereby forming a clear mark. At the same time, the laser beam has high precision and can be engraved without damaging the surface of the material, ensuring the quality and aesthetics of the product.

Features and Advantages of Laser Marking Equipment

1. High Precision: The use of laser technology can achieve micron-level precision, and the marking effect is clear and accurate.

2. High Speed: The laser marking speed is fast, and a large number of marking tasks can be completed in a short time, improving production efficiency.

3. Not Easy to Wear: Laser marking is to engrave on the surface of the material through a laser beam, which will not cause wear like traditional mechanical engraving, and can maintain clarity for a long time.

4. Multi-Function: The Stationary Laser Marking Machine can print a variety of information such as text, patterns, QR codes, etc., which can meet the needs of different industries.

5. Easy to Operate: The laser marking machine is computer-controlled, simple and convenient to operate, and does not require professional technicians to operate.

The application fields of laser marking machines are:

Laser Coding Machines are widely used in machinery manufacturing, electronic instruments, automotive parts and other fields.

1. Mechanical Manufacturing: Stainless steel is widely used to make high-quality parts, such as bearings, gears, connecting rods, etc. These parts require fine marking for easy tracking and management. Laser marking machines can mark these parts with high precision and high speed, ensuring the quality and safety of the parts.

2. Electronic Instruments: Laser marking machines are widely used in the identification and tracking of electronic products. For example, electronic products such as mobile phones and computers need to have serial numbers, production dates and other information engraved on their shells for after-sales service and quality tracking. Laser marking machines can engrave these electronic products with high precision and high speed, ensuring product quality and after-sales service.

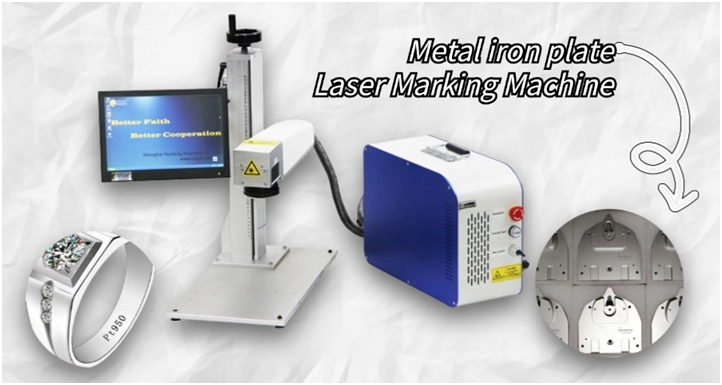

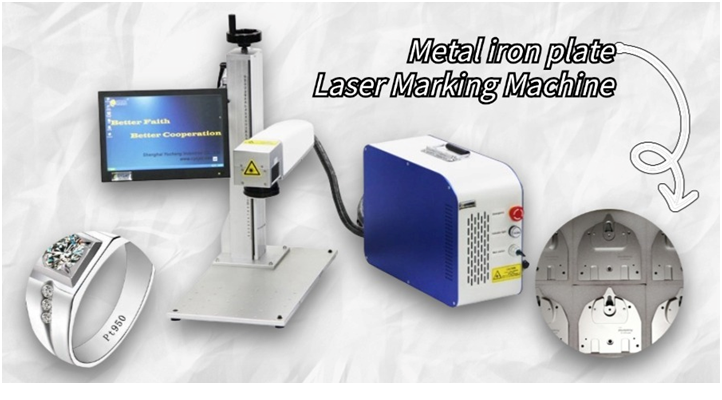

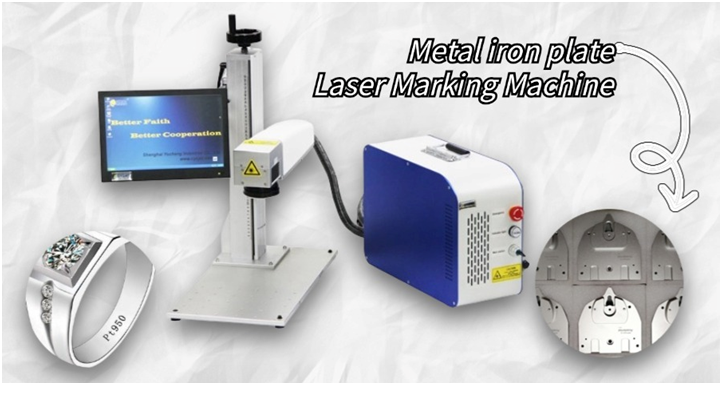

3. Auto Parts: Portable Desktop Laser Marking Machines are widely used in the identification and tracking of auto parts. For example, auto engine parts need to be engraved with information such as model and material on the surface for easy repair and maintenance. Laser marking machines can engrave these auto parts with high precision and high speed, ensuring the quality and safety of the car.

In addition, laser marking machines are also widely used in electronics, communications, machinery, automobiles, medical equipment, jewelry, watches and other industries. They can print information such as brand, specifications, production date, QR code, etc. on products to facilitate product traceability and management.

Use and Maintenance

When using the Laser Marking Machine, you need to follow the operating instructions to correctly start the machine, test the marking, and adjust the printing position. At the same time, in order to keep the equipment in good operating condition and extend its service life, regular maintenance and care are required. This includes cleaning the lens, checking the power cord, adjusting the laser head, and other steps.

In summary, the Fiber Laser Printer is a high-efficiency, high-precision and multi-functional marking equipment with broad application prospects in modern industrial production.

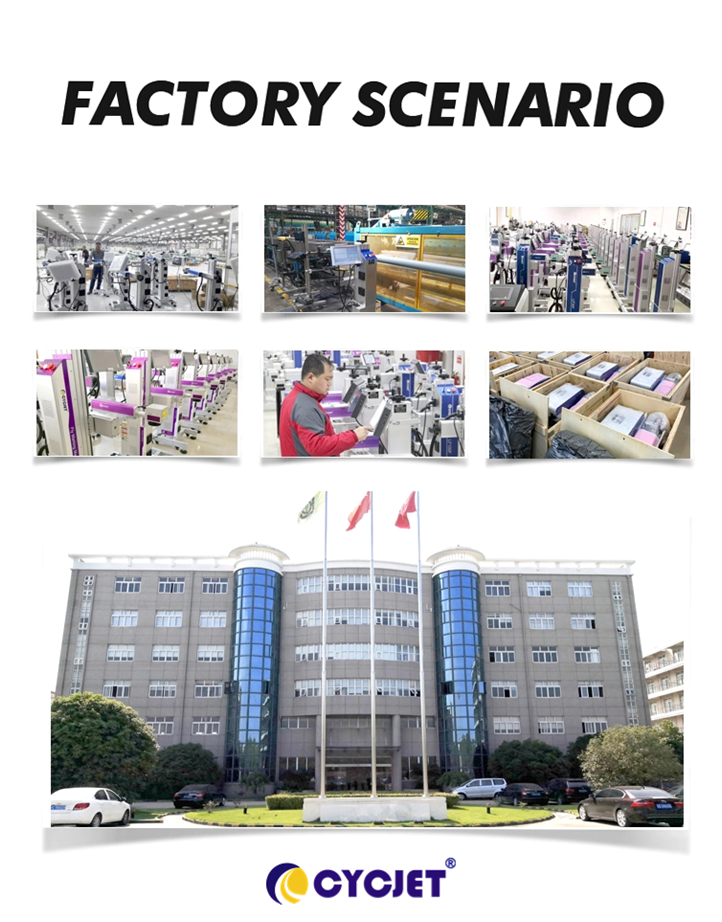

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 20 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Web: https://cycjet.com/

Reference Video: https://www.youtube.com/watch?v=BCgbd-bxavo

Facebook: https://www.facebook.com/100064098422560/videos/1799130023818781

Linkedin: https://www.linkedin.com/feed/update/urn:li:activity:6993870550787923968